WEET CR Sereis Carbon Film Resistor 1W 2WS 2W 3WS 3W 5WS Stably Controlled

WEE Technology Company Limited - WEE are Capacitors Specialist

What are the differences between carbon film resistance and metal film resistance

1. The carbon film resistance has a negative temperature coefficient, while the metal film resistance has a small positive temperature coefficient;

2. Carbon film resistance is an ordinary resistance, and its accuracy is generally not very high, while metal film resistance has higher accuracy than carbon film resistance. However, due to the improvement of current technology, this method is sometimes not very desirable;

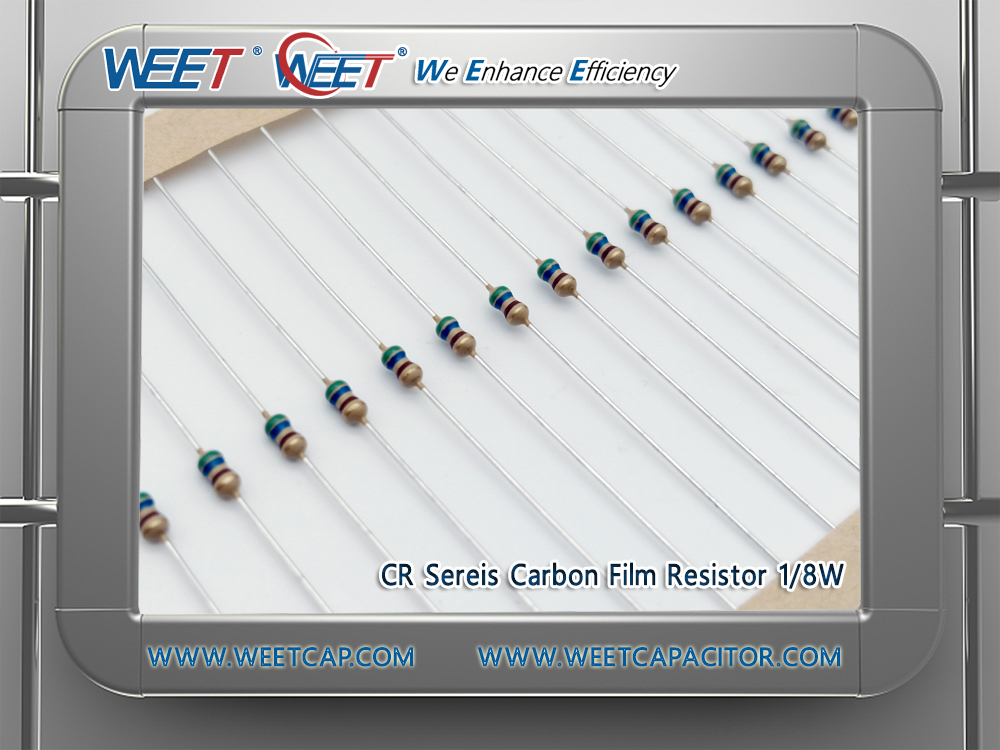

3. The appearance of carbon film resistors is mostly khaki or pink, while the appearance of metal film resistors is mostly blue;

4. By looking at the color of the protective paint, the black protective film is carbon film resistance, while the bright white protective film is metal film resistance.

What are the characteristics of carbon film resistance and metal film resistance

1、 Carbon film resistance

For the carbon film resistance, it uses carbon to precipitate on the magnetic rod or porcelain tube, and at the same time forms a layer of crystalline carbon film on its surface. By changing the thickness of the carbon film and changing the degree of the carbon film resistance by grooving, the required resistance value is finally obtained. Finally, the surface is coated with epoxy resin to strengthen the sealing. The appearance color is basically earthy yellow, but there are also other colors, such as pink.

The color ring is composed of four rings. The resistance range is 1 Ω~10M Ω. The rated power is 0.125W, 0.25W, 0.5W, 1W, etc. The accuracy range is ± 10%, ± 5%, ± 2%. This resistance is generally large and is often used in low-cost products, such as power supply products and chargers. This type of resistance is not recommended for starting resistance, because the impact resistance is relatively defective.

2、 Metal film resistance

As for the metal film resistor, it is formed by vacuum evaporation or infiltration on the ceramic pipe rack to form a layer of metal film, which is attached to the surface of white ceramics. It is cut to adjust the resistance value to obtain a more precise resistor. This resistor has high precision, small volume, good stability and high cost. It is usually used in wireless electronic equipment, especially in occasions with higher precision requirements. Its appearance color is mostly blue.