Dear Valued Clients,

Warm greetings as the Chinese Spring Festival (Year of the Horse 2026) approaches.

We would like to inform you of our upcoming Spring Festival holiday schedule:

Holiday period: February 7 – February 25, 2026

Resume work: February 26, 2026

During the holiday, order processing, shipment and customer service will be temporarily suspended. All inquiries and orders will be handled promptly upon our return.

We wish you a happy Spring Festival, prosperous business, and all the best in the Year of the Horse!

Contact us: info@weetcap.com

In the electronic component industry, stability and durability are non-negotiable core requirements for industrial equipment, outdoor electronics, and household appliances - especially when they operate in harsh high-temperature and high-humidity environments. The good news? Our WFC-A MPX X2 THB 85℃/85% capacitor can deliver this uncompromising reliability you need .

Wondering what the Double 85 standard really means? It requires capacitors to work continuously for 1000 hours at 85℃ high temperature and 85% relative humidity (RH) with rated voltage applied - all while keeping the capacitance change rate below 10%. This is a strict benchmark for industrial-grade reliability, and ordinary X2 capacitor simply can't measure up to it.

MPX X2 THB 85℃/85% capacitor boast an extremely wide range of applications, perfectly fitting scenarios like electric vehicle chargers, motor controllers, outdoor LED drivers, and more - anywhere reliable performance in harsh conditions is a must.

As a professional manufacturer of WFC-A MPX X2 THB 85℃/85%, we bring years of rich production experience and advanced testing equipment to the table - backed by international certifications including UL and VDE. To meet all your project needs, our double 85 X2 safety capacitors feature a complete specification system, with capacitance ranging from 0.0047μF to 10.0μF and rated voltage options of 275V, 305V, and 310V.

Contact us today to get free samples and test the unbeatable reliability of our MPX X2 THB 85℃/85% capacitor for yourself - no risk, no obligation!

More data:WEET WFCA THB 85 ℃ 85% X2 Metallized Polypropylene Film Capacitor 275V 305V 310VAC

Contact us:info@weetcap.com

WEE Technology Published on Jan 30, 2026

The WEET THB grades for film capacitor is a safety-approved X2 capacitor designed to withstand a high temperature of 85℃ and high humidity of 85% RH. It must be used in accordance with the principles of circuit matching and safety regulations; otherwise, the following consequences may arise:

1. Incorrect Connection Position (Most Critical)

Connecting the THB grades for film capacitor improperly between the live wire and protective earth (PE) will pose risks of electric leakage and electric shock.

2. Mismatched Voltage Specifications

Using a capacitor with a voltage rating lower than the circuit’s operating voltage may easily cause a short circuit, blow the fuse, and in extreme cases, even lead to electrolyte leakage from the capacitor casing and ignition of the circuit board.

Selecting a capacitor with excessively high capacitance will increase circuit power consumption and shorten service life. On the contrary, insufficient capacitance will fail to suppress electromagnetic interference (EMI), resulting in frequent device crashes.

3. Improper Soldering

Excessively high soldering temperature will cause the sealant between the THB grades for film capacitor pins and the main body to crack, thus losing its Dual 85 high temperature and humidity resistance. Mounting the capacitor close to heat-generating components may cause thermal expansion and bulging of the capacitor.

More details: WEET WFCA THB 85 ℃ 85% X2 Metallized Polypropylene Film Capacitor 275V 305V 310VAC

Contact us: Sales@weetcap.com

WEE Technology Published on Jan 23, 2026

We've all heard of X2 capacitors, but there's only one series that can withstand harsh environments - the WFC-A THB X2 series. It is a capacitor that passes the 85℃, 85% relative humidity (double 85) humidity and heat resistance test. Do you know where to use it?

INTRODUCTION

High-reliability home appliances

THB X2 series is used in the electronic control units of high-temperature and high-humidity home appliances such as dishwashers and disinfection cabinets.

Outdoor electrical equipment

It applies to outdoor LED street lamp power supplies and outdoor charging pile control modules.

These devices operate outdoors for long periods, exposed to high temperatures, high humidity, and heavy rain and snow, which accelerate the aging of ordinary capacitors.

Automotive electronics.

THB grade X2 film capacitor is adopted in the filter circuits of on-board chargers and battery management systems (BMS) for new energy vehicles.

The engine compartment is characterized by high temperature and humidity, coupled with extremely high safety requirements.

Free samples of the WEET WFC-A THB X2 series are available upon request. Please contact our sales team if you have any needs.

More details: WEET-WFCA-THB-X2-85C-Metallized-Polypropylene-Film-Capacitor-275V-305V-310VAC

WEE Technology Published On Jan 16, 2026

The WEET 305V 85/85 X2 Capacitor is a best-selling capacitor, all thanks to its inherent characteristics. So do you know why 85/85 X2 Capacitor is highly effective and durable?

INTRODUCTION

First, let WEET introduce its features.

It consists of a non-inductive grey plastic shell and grey epoxy resin. WFC-A outstanding THB capacitor reliability allows it to be connected in series for high-stability applications—such as watt-hour meters, LED drivers - and it can even maintain high stability in extremely harsh environments.

85/85 X2 Capacitor Specifications

Operating Temperature: -40°C ~ +110°C

Capacitance Range: 0.0047 ~ 10.0 μF

Rated Voltage: 275V, 305V, 310VAC

Packaging: Bulk & Tape-and-Reel

Capacitance Tolerance: ±10%

Notes:

85/85 X2 Capacitors pins are available in different lengths, and customization is available according to your specific requirements.

WEET WFCA THB 85 ℃ 85% X2 Metallized Polypropylene Film Capacitor 275V 305V 310VAC

Contact us: Sales@weetcap.com

WEE Technology Published on Jan 9, 2026

It is a component that integrates both a resistor and a capacitor, and is generally referred to as an X2 RC network.

So how can we judge X2 safety capacitor RC quality?

INTRODUCTION

The core method is to verify its capacitor section and built-in resistor section separately, combined with a visual inspection.

The commonly used tool is a digital multimeter.

Below are the detailed steps:

1. Visual Inspection

Check the appearance of the X2 Safety Capacitor RC for signs of cracking, deformation, or charring.

Examine whether the pins have issues such as severe oxidation, corrosion, or breakage.

Verify if the specification parameters on the surface are illegible.

2. Testing the X2 Safety Capacitor RC Built-in Resistor

The resistance value of the built-in resistor in an X2 RC snubber for AC power typically ranges from 1MΩ to 10MΩ.

Touch the two pins of the component with the probes of the digital multimeter respectively.

If the displayed resistance value matches the nominal value or the deviation is within ±10%, the resistor section is in normal condition.

3. Insulation Test

Touch the X2 Safety Capacitor RC two pins with the multimeter probes.

If the display shows OL, the insulation is good and there is no leakage.

If a numerical value is displayed and the buzzer sounds, the capacitor has leakage and is unfit for use.

Contact us:Sales@weetcap.com

WEE Technology Published on Dec 26, 2025

I believe everyone is familiar with X2 capacitors, but have you ever seen an X2 capacitor with a built-in resistor? How much do you know about RC Unit X2 Film Capacitors?

Introduction

RC Unit X2 Film Capacitors refer to X2 metallized film safety capacitors with integrated resistors.

They are integrated RC components that combine X2 film capacitors and resistors in a single package.

X2 Snubber Capacitor Details:

Rated Voltage: 275VAC

Capacitance Range: 1.0Μf

Capacitance Tolerance: ±10% (K)

Operating Temperature: -40℃~100℃

Tin-plated Wire Length: 40±5mm

X2 Snubber Capacitor Encapsulated in a flame-retardant plastic case with radial leads, these capacitors facilitate easy PCB mounting and comply with RoHS and environmental requirements.

RC Unit X2 Film Capacitors Standard Dimensions: L: 31.5mm, T: 10.8mm, H: 19.5mm

Customization is available. Please feel free to contact us if you have any custom requirements.

Contact us:Sales@weetcap.com

WEE Technology Published on Dec 19, 2025

Superes Resistor are commonly used in industrial equipment, circuits, and medical devices. But are there resistors specifically designed for audio applications?

The answer is yes. Let's introduce an audio-specific resistor – the Audio-Grade Superes Resistor.

Introduction

Features:

Superes Resistor is a wire wound resistor, fabricated by winding resistance wire.

It boasts excellent long-term stability.

It is corrosion-resistant, heat-resistant, and moisture-proof, capable of withstanding a wide range of harsh environments.

Dimensions:

Taking the 5W Superes Resistor (as shown in the figure below) as an example:

L: 24.5±1.0

H: 38±1.0

Operating Temp. Range: -55℃~ +155℃

There are multiple standard tolerances available, including ±1%, ±2%, and ±5%.

Contact us:Sales@weetcap.com

WEE Technology Published on Dec 4, 2025

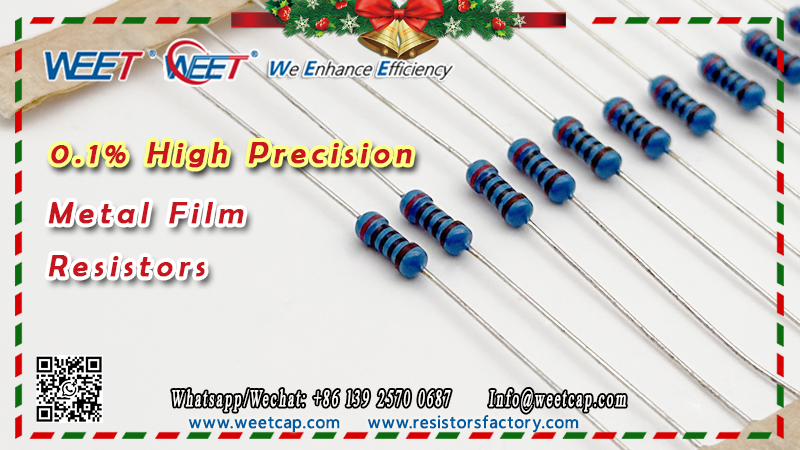

MF 0.1% High Precision Metal Film Resistors are a widely used type of resistor. Literally speaking, they are metal resistors with leads at both ends. Have you ever carefully observed the color bands on them? What do they mean? How to identify the colors of 5-band metal film resistors?

Let WEET guide you to distinguish these colorful bands!

Introduction

First of all, the color band marking of 5-Band Metal Film Resistors contains three types of information: significant figures, multiplier, and tolerance. Different colors on the resistor represent different values. Next, I will list the corresponding values of each color one by one: Black = 0; Brown = 1; Red = 2; Orange = 3; Yellow = 4; Green = 5; Blue = 6; Purple = 7; Gray = 8; White = 9

1st band = First significant figure

2nd band = Second significant figure

3rd band = Third significant figure

4th band = Multiplier

5th band = Tolerance

Take the MF 5-Band Metal Film Resistors in the figure as an example, with color bands of red, black, black, black, brown:

Significant figures: Red = 2, Black = 0, Black = 0

Multiplier: Black = 10⁰ = 1

Tolerance: Brown = ±1%

Calculation result: 200 × 10⁰ = 200Ω (with a tolerance of ±1%)

After such an explanation from WEET, isn't it easy to identify the colors of 5-Band Metal Film Resistors?

Contact us:Sales@weetcap.com

WEE Technology Published on Dec 3, 2025

WEET offers an extensive range of ceramic resistors - How many types of ceramic power resistors have you explored?

Our cement resistor 5W / 10W / 20W / 50W includes axial cement resistors, vertical cement-cased ceramic resistors, radial cement-cased ceramic resistors, and more.

Below is a brief introduction to WEET high wattage cement resistor:

1. Key Features

High temperature resistance.

Excellent heat dissipation.

Superior stability.

2. Application Scenarios

Daily electronic devices: Air conditioners, mobile phones, LED lighting, car chargers.

Industrial & power equipment: Inverters, charging piles, machine tools, wind power converters.

Special scenarios: Satellites, nuclear magnetic resonance (NMR) equipment, radar systems.

3. Ceramic Power Resistors vs Ordinary Resistors

Ordinary Resistors (Carbon Film/Metal Film): Compact size, but poor high-temperature resistance. Suitable for low-power,

normal-temperature environments.

Ceramic Power Resistors: Relatively larger size, excellent high-temperature resistance. Ideal for high-power, high-temperature,

and harsh environments.

Contact us:Sales@weetcap.com

WEE Technology Published on Nov 28, 2025