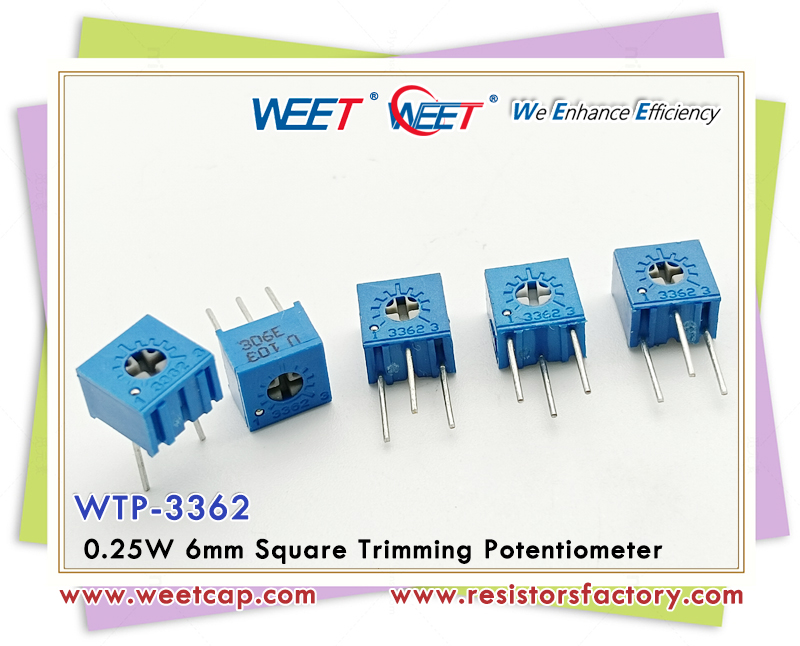

WEET WTP 3362 0.25W 6mm Square Trimming Potentiometer 9 Terminal Styles

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

Trouble shooting of Timming potentiometer soldering

The soldering of potentiometers is one of the reasons that can easily cause malfunctions, and most customers still use manual soldering.

In addition, some large enterprises use high-frequency soldering methods.

There are some things to pay attention to. When using manual soldering method, the potentiometer should be completed as quickly as possible during the soldering operation, preferably within 3 seconds.

The highest temperature of the soldering iron contact should be below 270 degrees.

If the time is too long or the temperature is too high, it can cause various reasons such as poor contact of the potentiometer.

When welding, be cautious when using flux and avoid using water-soluble flux, otherwise it will promote metal oxidation and material mold.

When using high-frequency soldering, pay attention to the plastic parts inside the potentiometer, such as the dial knob, plastic push handle, plastic handle, etc.,

so that the melting point can reach the required temperature for high-frequency soldering. If not, please replace the high-temperature resistant parts.

https://www.resistorsfactory.com/Datasheet/WEET-WTP-3362-0.25W-6mm-Square-Trimming-Potentiometer.pdf