WEE Technology Company Limited - WEE are Capacitors Specialist

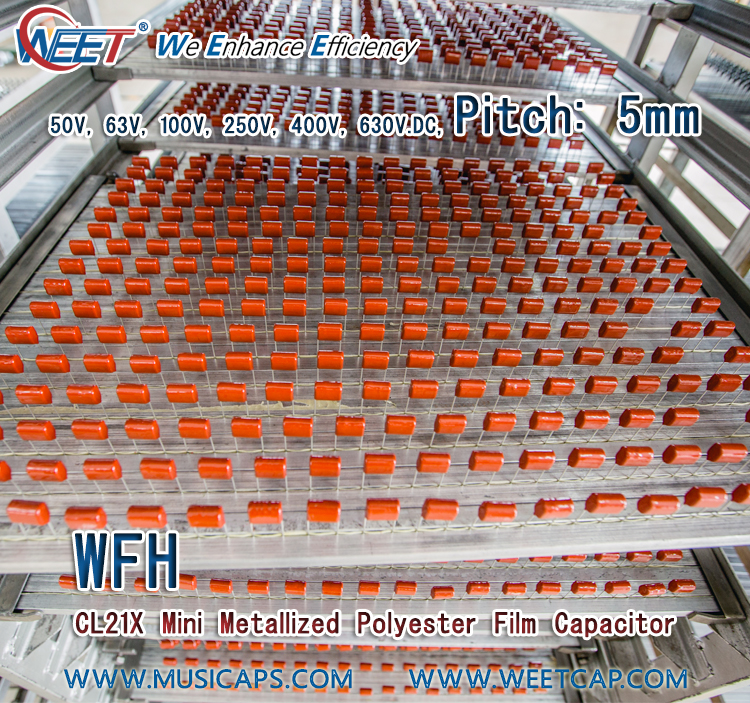

CBB21X and CL21X belong to ultra small thin film capacitors. In many circuits, the volume of capacitors is very small. The traditional CBB21 and CL21 capacitors with large volume are no longer suitable. At this time, CBB21X and CL21X capacitors can be used.

CL21X is a subminiature metallized polyester film capacitor. Its advantages are high temperature resistance of 120 ℃ and small size. Its disadvantages are that its loss is higher than that of CBB21X, so it can only be used in DC and low pulse occasions.

CBB21X is a subminiature metallized polypropylene film capacitor, which is resistant to high temperature of 105 ℃, low loss, ≤ 0.0008%, and small internal temperature rise. It is suitable for various circuits with large AC and DC pulses, and is mostly used in circuits requiring small size, low loss and high stability.

It is difficult to see the difference between the two capacitors from the appearance. The CL21X capacitor is used more, but CBB21X has small loss, good stability and high reliability, and can be used in circuits with higher frequency.

The smaller the film capacitor, the better the production?

At present, capacitors are developing towards miniaturization. However, from the perspective of production difficulty, the smaller the size, the greater the difficulty of production. Therefore, most capacitor manufacturers in the industry are only good at producing large capacitors, not small capacitors.

Check more detalis at below link for WFH CL21X specifications:

https://www.weetcap.com/pdf/WEET-WFH-Mini-Metallized-Polyester-Film-Capacitors.pdf

WEE Technology Company Limited - WEE are Capacitors Specialist

In the past, the most commonly used thin-film capacitors were CBB22 capacitor and CL21 capacitor. Among them, CL21 capacitor was largely replaced by CBB22 capacitor, and the frequency of CL21 capacitor was less and less. However, now there is a CL21X capacitor, which has become particularly large. What is CL21X capacitor? What are its characteristics and functions?

CL21X subminiature polyester film capacitor

The full name of CL21x capacitor is metallized polyester film subminiature capacitor. We know that the biggest advantage of CL capacitor compared with CBB capacitor is smaller volume and higher temperature resistance. Therefore, polyester film is often selected when making subminiature capacitor, which can make the capacitor volume smaller. This is also one reason why CL21X capacitor has more users.

Structure of CL21X capacitor

Medium: polyester film

Electrode: metal vacuum evaporation layer (aluminum)

Package: flame retardant epoxy resin (UL94 V-0)

Lead: tinned copper-clad steel wire (CP wire) or tinned copper wire

Characteristics and functions of CL21X capacitor

The volume of CL21X capacitor is very small and has good self-healing; Good appearance consistency; High reliability.

It is mostly used in DC and low pulse occasions. Such as low-frequency filtering, DC isolation, bypass and coupling, etc.

Check more details at : https://www.weetcap.com/Plastic-Film-Capacitors/WEET-WFH-CL21X-Mini-Metallized-Polyester-Film-Capacitor.html

WEE Technology Company Limited - WEE are Capacitors Specialist

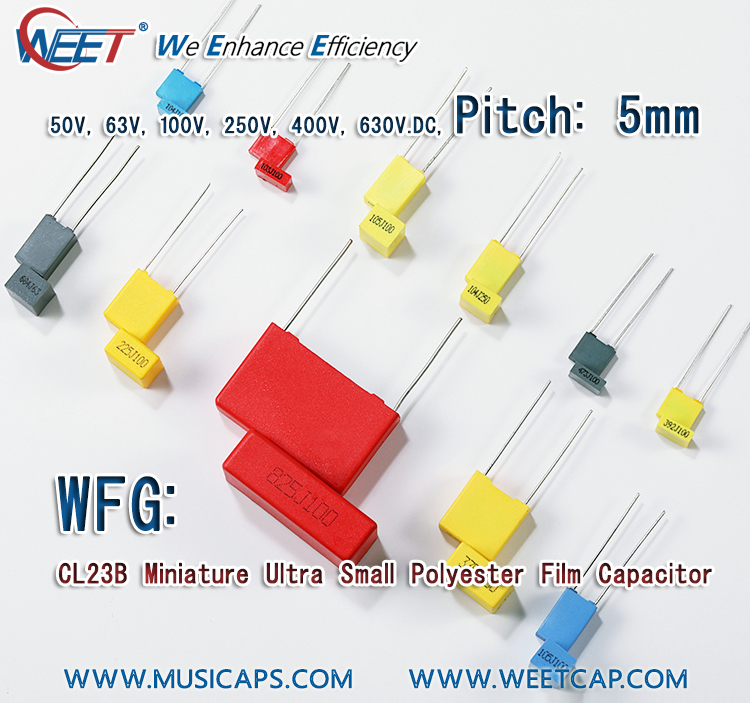

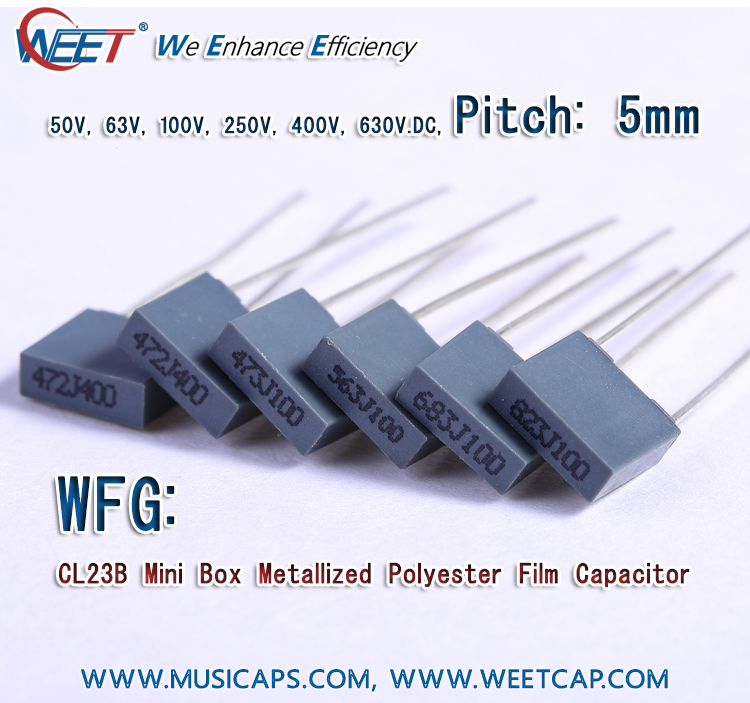

What is the difference between CL71 and CL23B

1. CL71 is a correction capacitor of laminated structure.

CL71 is indeed a correction capacitor, but it belongs to the internal structure and is laminated. In fact, CL23B and CL71 belong to non inductive winding, but CL71 capacitor basically has no inductance, while CL23B has a small amount of inductance. However, the disadvantage of CL71 capacitor is that the production is complex and the production equipment is very expensive. At present, it is very rare for domestic manufacturers to produce CL71 capacitor.

2. CL23B is a winding correction capacitor.

The correction capacitors we see on the market are basically CL23B metallized polyester film wound capacitors. They belong to ultra-small polyester film capacitors, also known as minbox capacitors. It is much less difficult to produce. Most manufacturers who are good at producing small film capacitors can produce them, and the equipment used is relatively common.

Small boxed film capacitors CL23B series use metallized polyethylene film as medium and electrode, non inductive winding structure, encapsulated in small plastic shell and filled with epoxy resin. CL23B series correction capacitors are suitable for various applications of MEF series, especially those with high requirements for capacitor size and square appearance.

Characteristics and functions of CL23B correction capacitor: small volume, light weight, wide capacity range and large ratio capacity; Good self-healing and long service life; Applicable to DC isolation, bypass, coupling and filtering of DC and VHF signals; It is especially suitable for color TV, SPC exchange and military machine LCD monitor rectification, automotive DC motor interference suppression and other occasion

https://www.weetcap.com/Plastic-Film-Capacitors/

WFG CL23B Mini Box Metallized Polyester Film Capacitor Standard Capacitance, voltage and size table.

For other values, please contact with our sales for more details.

| CODE | UF | 63V | 100V | 250VDC | 400VDC | 630VDC | (W*H*T) |

| 102 | 0.001 | M1 | M1 | M1,M2 | M2,M3 | M2,M3 | M1:7.2*6.5*2.5 |

| 152 | 0.0015 | M1 | M1 | M1,M2 | M2,M3 | M2,M3 | M2:7.2*7.5*3.5 |

| 222 | 0.0022 | M1 | M1 | M1,M2 | M2,M3 | M2,M3 | M3:7.2*9.5*4.5 |

| 332 | 0.0033 | M1 | M1 | M1,M2 | M2,M3 | M2,M3 | M4:7.2*10*5 |

| 472 | 0.0047 | M1 | M1 | M1,M2 | M2,M3 | M2,M3 | M5:7.2*11*6 |

| 682 | 0.0068 | M1 | M1 | M1,M2 | M2,M3 | M2,M3 | |

| 103 | 0.01 | M1 | M1 | M1,M2 | M2,M3 | M3 | |

| 153 | 0.015 | M1 | M1 | M1,M2 | M2,M3 | M3,M4 | |

| 223 | 0.022 | M1 | M1 | M1,M2 | M2,M3 | M4,M5 | |

| 333 | 0.033 | M1 | M1 | M1,M2 | M2,M3 | M4,M5 | |

| 473 | 0.047 | M1 | M1 | M1,M2 | M2,M3 | ||

| 683 | 0.068 | M1 | M1 | M2,M3 | M3,M4 | ||

| 104 | 0.1 | M1 | M1 | M3 | M4 | ||

| 154 | 0.15 | M1 | M1 | M3,M4 | M4,M5 | ||

| 224 | 0.22 | M1 | M1,M2 | M5 | M5 | ||

| 334 | 0.33 | M2,M3 | M2,M3 | M5 | |||

| 474 | 0.47 | M2,M3,M4 | M2,M3,M4 | ||||

| 684 | 0.68 | M4,M5 | M4,M5 | ||||

| 105 | 1.0 | M5 | M5 | ||||

| 155 | 1.5 | M5 |

WEE Technology Company Limited - WEE are Capacitors Specialist

Sometimes, there may be many names for the same capacitor. Because of its many names, it is easy to confuse people. Is CL23B a correction capacitor?

In fact, there are many kinds of correction capacitors. For example, the winding type is called CL23B capacitor, and the other is CL71 capacitor with laminated structure. Even the correction capacitor is also called minibox capacitor, miniaturized boxed capacitor, ultra-small boxed capacitor, etc. in fact, they all refer to a kind of capacitor, that is, correction capacitor.

Small boxed film capacitors CL23B series use metallized polyethylene film as medium and electrode, non inductive structure, encapsulated in small plastic shell and filled with epoxy resin.

The capacitor has small volume and good appearance consistency. It is especially used in some circuit occasions requiring small capacitance volume. It is mostly used in all kinds of low-power and low-frequency circuits.

This kind of capacitor is encapsulated with plastic shell. The common colors are yellow, gray, red and blue. Although the colors are different, the performance is not much different, and the functions are the same.

| Operating Temperature: | -40℃~ +100℃ , 40/100/21 |

| Rated Voltage(V.DC): | 50V, 63V, 100V, 250V, 400V, 630V. |

| Capacitance Range: | 0.001 ~ 2.2µF |

| Capacitance Tolerance: | ±5%, ±10%, ±20% |

| Insulation Resistance: | UR≤100V C≤0.33µF ≥3750MΩ |

| C>0.33µF ≥1250S | |

| UR>100V C≤0.33µF ≥7500MΩ | |

| C>0.33µF ≥2500S | |

| (20℃ 100VDC 60SEC) P.S: T[s]=I.R.[MΩ]*CN [µF] | |

| Dissipation Factor: | ≤0.01 (at 1KHz 20℃) |

WEE Technology Company Limited - WEE are Capacitors Specialist

WEET WFG CL23B Mini Box Metallized Polyester Film Capacitor Features:

Miniature size, Rounded by metalized polyester film, good self-healing effect

Moisture-proof, flame retardant, some small capacitance can be used in series film

Low dissipation factor, high voltage, box type by the epoxy potting

Good self-healing effect, good stability and reliability

WEET WFG CL23B Mini Box Metallized Polyester Film Capacitor Main Applications:

Identical appearance is applicable to all kinds of low dissipation and high precision capacitance circuits

Widely used for DC low pulse portion of occasions, typical applications are amplifier, TV, communications, power supply and other products requiring high reliability circuit

WEET WFG CL23B Mini Box Metallized Polyester Film Capacitor Datasheet:

https://www.weetcap.com/pdf/WEET-WFG-Mini-Box-Metallized-Polyester-Film-Capacitors-CL23B.pdf

WEE Technology Company Limited - WEE are Capacitors Specialist

WEE Technology can produce and offer you full series of film capacitors under our own trademark WEET.

Different dielectric materials:polyester film capacitors, Box type polypropylene film capacitors, Dip type polypropylene film capacitors

Tolerance range:±1%, ±2%, ±2.5%, ±5%, ±10%

Temperature range:normally film capacitors temperature range is -40'C to 85'C, for some series we can provide a wide temperature range up to 125'C.

Technology available:Winding technology and stacked technology, single side metallized structure and metallized structure

Safety Approvals of film capacitors:RoHS REACH ENEC, VDE, UL, TUV, CE

Packaging:Ammo/Tape packaging and Bulk packaging both available

WEET All Kinds of Capacitors Cross Reference Guide

WEE Technology Company Limited - WEE are Capacitors Specialist

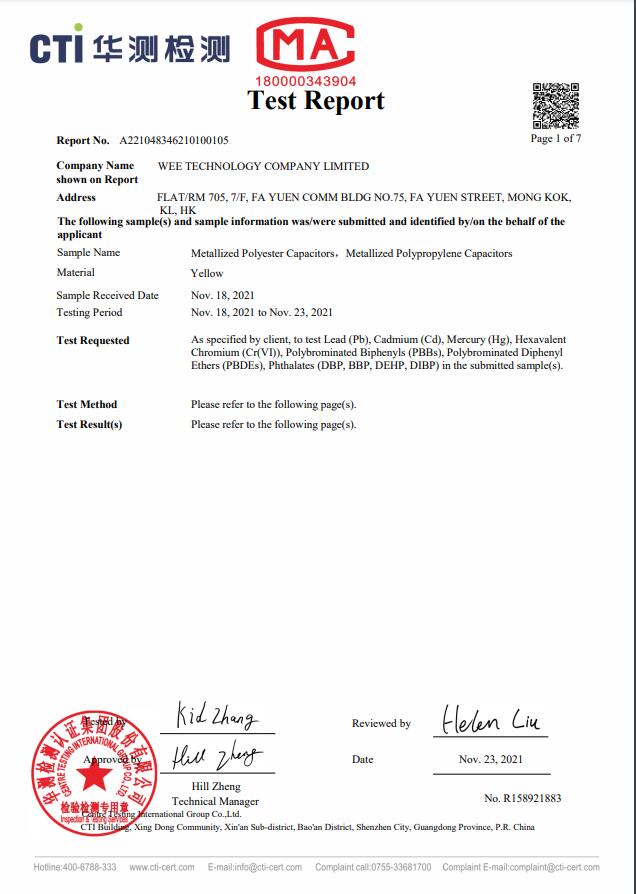

WEET Polyester and Polypropylene Film Capacitor RoHS REACH Halogen Test Report

WEE Technology Company Limited - WEE are Capacitors Specialist

Dear Customers,

How time flies! We are going to say goodbye to year 2021 and welcome the New Year 2022.

In 2021, we are all still undergoing a long process of COVID-19 all over the world. The economy is going down globally.

Some of our competitors even shut down factory and is wielding the jobs cutting acts in a big way.

However, WEET 2021 annual turnover is surprisingly stable and even better than the past years.

WEET wholeheartedly thank for all the customers’ supports and trust.

In 2022, we are expecting a fresh new year, the COVID-19 is gone forever. The entire business field is thriving and prosperous.

WEET has planned to expand Capacitors factory and greatly promote capacitors under WEET brand.

Without your support, WEET is ZERO.

WEET success is greatly depends on our valuable customers. Let us make the best of 2022 to build our business partnership.

Yours Sincerely,

From your faithful and supportive friend

WEE Technology Company Limited

WEE Technology Company Limited - WEE are Capacitors Specialist

We are glad to inform you that we have resume work from National holiday on Oct 8th.

Before the holiday, we got a sample request from one of our cusotmer for WFB MKP Metallized Polypropylene Film Capacitor CBB21 3.0µF ±10% 250VDC 30*22*13mmMax Pitch 27.5mm Bulk RoHS.

We thought the lead time will be longer due to holiday. However, we made out 15pcs of the samples in three days.

I am really impressed by the efficiency of our work and good disciplined of our company.

It is a great honor to with with WEET team numbers.

WEE Technology Company Limited - WEE are Capacitors Specialist

Recently, WEET successfully helped out a United Kingdom customer with their new project. As told by the customer that their each PCB board needs four pieces of 1.8uF +/-10% 250VDC MKT yellow film capacitor, but due to the original design and space limitation of the PCB board, there is very tight room to put that four pieces of MKT capacitors, and they have very strict requirement for the dimension, especially the diameter, not bigger than 9mm.

Before they contacted with us, they also consulted with other suppliers in China, but all in vain. Finally, WEET engineers studies their PCB drawing and outline, we made our 20 pieces samples to them in a week. After the tested the samples, they all excited to know that WEET WMA series is perfect for them, not only for capacitors size, but also for performance. Without further hesitation, they placed mass production order to us.

Here we would like to thank the customers for their support and confidence in WEET capacitors, also we are pleased with WEET engineers. Let us work together to find the best solution to your requirements, cheers!