The main difference between aluminum polymer capacitors and traditional aluminum electrolytic capacitors

lies in their construction and the electrolyte materials used, which lead to significant differences in their performance:

Electrolyte material:

Traditional aluminum electrolytic capacitors typically use liquid electrolytes (such as borate solutions) or in some cases semi-solid paste electrolytes.

Aluminum polymer capacitors use conductive polymers as cathode materials, which are solid electrolytes commonly found in materials such as polypyrrole and polythiophene.

Equivalent series resistance (ESR):

Aluminum polymer capacitors typically have very low ESR due to the high conductivity of solid electrolytes, which makes them more outstanding in high-frequency applications,

effectively filtering out ripple currents and reducing noise.

Traditional aluminum electrolytic capacitors have lower high-frequency performance compared to polymer capacitors due to the higher resistance and ESR of liquid electrolytes.

Temperature stability:

The capacitance of polymer capacitors changes little with temperature and has good temperature stability.

Capacitors with liquid electrolytes are greatly affected by temperature, and their capacitance and ESR will vary significantly with temperature.

Lifespan and reliability:

Aluminum polymer capacitors have no liquid leakage or drying problems, reducing the risk of bloating and bursting, longer lifespan, and higher reliability.

The electrolyte of traditional aluminum electrolytic capacitors may evaporate or dry over time, leading to a decrease in capacitance value and eventual failure.

Physical form:

Polymer capacitors can achieve smaller size and lighter weight, making them suitable for high-density packaging and miniaturization design.

Traditional aluminum electrolytic capacitors may require more space to accommodate and prevent leakage due to the liquid electrolyte.

Applicable fields:

Aluminum polymer capacitors are more suitable for high demand applications such as high-end motherboards, power converters, automotive electronics,

high-frequency communication equipment, etc. due to their superior performance.

Traditional aluminum electrolytic capacitors still hold a place in cost sensitive fields with less stringent requirements for volume and performance.

Aluminum polymer capacitors are superior to traditional aluminum electrolytic capacitors in terms of high-frequency performance, temperature stability,

lifespan, and reliability, but correspondingly, the cost may also be higher. The choice of which type of capacitor to use depends on the specific application requirements and budget.

Aluminum polymer capacitors play an important role in multiple fields and applications due to their unique performance advantages.

The following are some of the main application areas:

Consumer electronics: In smartphones, tablets, laptops, and other portable devices, aluminum polymer capacitors are used for power management,

decoupling of CPUs and GPUs, and high-frequency filtering to help improve device energy efficiency and stability.

Computer hardware: In motherboards, graphics cards, memory modules, and solid-state drives,

they are used to provide fast response power supply, ensuring high-performance computing and signal purity.

Power Conversion and Adapter: In switching power supplies, AC-DC converters, and DC-DC converters,

aluminum polymer capacitors provide low ESR characteristics that help improve energy efficiency, reduce heat generation, and maintain stable output under high-frequency conditions.

Automotive electronics: In the engine control units, advanced driver assistance systems (ADAS),

and infotainment systems of automobiles, their high reliability, wide temperature range, and seismic performance are particularly suitable.

Telecommunications and network equipment: In communication infrastructure such as base stations, routers, and switches,

aluminum polymer capacitors are used for filtering, energy storage, and maintaining signal quality, supporting high-speed data transmission and long-term stable operation.

Renewable energy: In solar inverters and wind power control systems, they help smooth output voltage,

improve energy efficiency, and maintain stable operation in harsh environments.

Medical equipment: In precision medical instruments and monitoring systems, the stability and long lifespan of

aluminum polymer capacitors ensure the reliability of the equipment and patient safety.

Aerospace: In aviation electronic equipment and satellite communication systems,

their high performance and reliability meet the requirements for use in extreme environments.

Preheating the circuit board to reduce thermal shock is a necessary step during welding,

and it is recommended to preheat it to about 100-120 ° C.

The welding temperature should be controlled below 260 ° C and the welding time should be shortened

as much as possible to avoid capacitor failure caused by overheating.

Use appropriate solder and flux, and ensure that the solder joints are uniform to avoid local overheating.

The life span of aluminum polymer capacitors is usually represented by a warranty period of thousands to tens of thousands of hours,

but the actual service life is affected by various factors, including operating temperature, voltage fluctuations, and mechanical stress.

High temperature is the main factor that shortens the lifespan of capacitors, and for every 10 ° C increase,

the lifespan is approximately halved. Voltage fluctuations should be controlled within the rated voltage range,

as over voltage can accelerate aging. In addition, mechanical vibration and impact also need to be considered,

and reasonable design and installation can effectively avoid these problems.

The main advantages of aluminum polymer capacitors include:

Lower equivalent series resistance (ESR) allows them to perform better in high-frequency circuits, effectively filtering out ripple current and noise.

Higher temperature stability, wider operating temperature range, suitable for use in harsh environments.

Don't worry about electrolyte drying up, it has a longer service life and higher reliability.

Not easy to leak and low risk of explosion, as there is no liquid electrolyte, there is a significant improvement in safety.

Small in size and lightweight, suitable for portable electronic devices and high-density assembly applications

Working principle of aluminum polymer capacitors

The core of aluminum polymer capacitors lies in their solid polymer electrolyte, which replaces the liquid electrolyte in traditional aluminum electrolytic capacitors.

This polymer material not only improves the stability and high temperature resistance of capacitors, but also significantly reduces ESR.

When working, the positive electrode is made of aluminum foil, and a layer of aluminum oxide film is formed on the surface as a dielectric;

The negative electrode is made of aluminum foil coated with conductive polymer.

Ionic conduction is achieved between the two poles through solid polymer electrolytes, enabling the storage and release of charges.

This mechanism endows aluminum polymer capacitors with excellent electrical performance.

Aluminum polymer capacitor is an electrolytic capacitor that has gradually become a favored choice for engineers in the field of electronic components

due to its excellent performance, especially in applications with strict requirements for capacitance characteristics.

Its characteristic is to use aluminum foil as the anode and form a layer of aluminum oxide (Al2O3) on the surface of the anode as the dielectric.

Unlike traditional liquid aluminum electrolytic capacitors, the cathode of aluminum polymer capacitors does not use liquid electrolyte,

but instead uses a conductive polymer material. This high conductivity polymer electrode film is deposited on an alumina layer,

replacing traditional liquid or paste electrolytes, and is therefore also known as solid-state aluminum electrolytic capacitors.

Aluminum polymer capacitors use solid polymer electrolytes, which have high conductivity, low ESR, wide temperature operating range, and long lifespan.

Suitable for scenarios with high frequency, harsh environments, and high reliability requirements,

such as consumer electronics, automotive electronics, and telecommunications equipment.

Compared with traditional aluminum electrolytic capacitors, it has better performance but may be more expensive.

Dear Customers,

We are glad to inform you the 2024 marks the 75th anniversary of China National Day, which is also the 75th anniversary of the founding of the People's Republic of China.

Our factory is running into the peak season from Sept to Dec,2024.

We sincerely suggest you plan your order in advance, we will try our best to provide the fastest lead time to meet your schedule. Thank you.

2024 National Day Holiday Notice

Holiday From 1st Oct, to 7th Oct, Resume Work On 8th Oct, 2024

Best regards,

WEE Technology Company Limited

2024-09-20

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

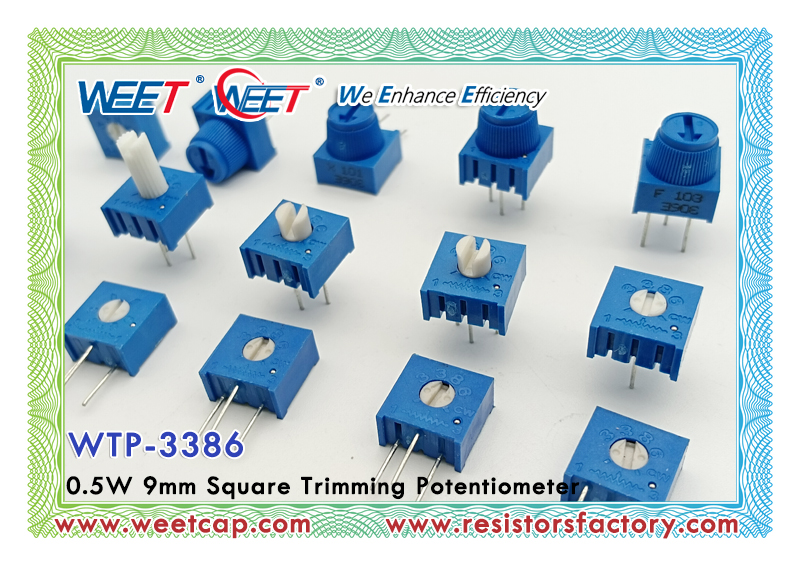

Precautions for using WEET potentiometers:

(1) In order to prevent the pin contacts and conductive layer of the WEET potentiometer from deteriorating or burning out, the working current of the potentiometer should not exceed the rated current.

To avoid potential damage to the potentiometer.

(2) If the WEET potentiometer is used for a long time, there may be some loud noise or inflexible shaft adjustment.

In this case, there may be a lack of specialized lubricating oil inside the potentiometer.

By adding appropriate lubricating oil, the two types of faults can be solved.

(3) Do not tap or shake the WEET potentiometer during installation. Because the interior of the potentiometer is composed of various components,

it is possible that these components may fall off due to violent shaking or vibration. So, more precautions are needed for this.

https://www.resistorsfactory.com/Datasheet/WEET-WTP-3386-0.5W-9mm-Square-Trimming-Potentiometer.pdf

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

| Standard Resistance Range | 10Ω - 5MΩ |

| Resistance Tolerance | ±10% (100Ω~1M), ±20% (R<100Ω, >1M) |

| Terminal Resistance | ≤±1%R or 2Ω (whichever is greater) |

| Contact Resistance Variation | (CRV) ≤±1%R or 3Ω, (whichever is greater) |

| Insulation Resistance | ≥1GΩ (100V AC) |

| Withstand Voltage | 640V AC |

| Adjustment Angle | 240° |

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

The working principle of the 3296 potentiometer is based on its internal structure and electrical characteristics.

It is a variable resistor, usually composed of a resistor body and a movable brush. The resistor body has two fixed ends, and the position of the moving contact point on the resistor body can be changed by manually adjusting the shaft or sliding handle. In this way, the resistance value between the moving contact and any fixed end will change, thereby adjusting the voltage and current in the circuit. twelve The 3296 potentiometer is a pre adjusted potentiometer driven by a screw, with the characteristic of multiple rotations. The full stroke is greater than or equal to 15 rotations, and the maximum resistance of the resistor body is only 300 °.

By rotating the screw, the position of the contact point on the resistor can be adjusted, thereby changing the resistance value of the potentiometer. After adjusting to the maximum or minimum resistance value, the contact will not move with further rotation of the screw, which provides protection.

Potentiometers have a wide range of applications, as they can be used to adjust voltage (including DC voltage and signal voltage) and current, and are also commonly used as voltage dividers. In electronic circuits, the 3296 potentiometer is particularly suitable for situations that require high precision, such as audio amplifiers, temperature controllers, light brightness regulators, etc

https://www.resistorsfactory.com/Datasheet/WEET-WTP-3329-0.5W-6mm-Round-Trimming-Potentiometer.pdf

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

How to distinguish the three pins of a potentiometer

The three pins of a potentiometer typically include the middle pin (wiper), top pin (top), and bottom pin (bottom).

The middle foot serves as a voltage divider, while the top and bottom feet define the resistance range that changes when the knob is turned. The method to distinguish the three pins of a potentiometer is as follows: 12 Observe the appearance. The appearance of a potentiometer usually has a mark indicating the position of the middle pin, and the positions of the left and right pins can also be distinguished by size and shape. Generally, the left pin is slightly larger than the right pin and is further away from the middle pin.

Use a multimeter for testing. Using a multimeter can further confirm the function of the pins. Firstly, connect the multimeter probes to any two pins of the potentiometer, adjust the potentiometer handle, and observe whether the resistance changes; Then, replace one of the probes with the connected pin, adjust the potentiometer handle again, and observe whether the resistance value changes. Comparing the resistance values of two measurements, when the resistance value in one measurement does not change, it indicates that the pin connected to the red and black probes of the multimeter is a fixed pin, and the other pin is a moving pin. Through these methods, the three pins of the potentiometer can be effectively distinguished.

https://www.resistorsfactory.com/Datasheet/WEET-WTP-3323-0.25W-6mm-Square-Trimming-Potentiometer.pdf