WEE Technology Company Limited - WEE are Capacitors Specialist

There are several kinds of non-polar aluminum electrolytic capacitors.

The basic characteristics of the non-polar electrolytic capacitor have not been changed, but some measures have been taken in the structure, which can be used in reverse.

Whether it can be used in AC circuits and circuits with large ripple current depends on other properties, such as the temperature rise of capacitors, the impedance frequency characteristics of capacitors, etc.

According to different uses, there are many types of non-polar aluminum electrolytic capacitors. The following introduces several small non-polar aluminum electrolytic capacitors with different characteristic levels.

1) Non polar aluminum electrolytic capacitor. Here "general" means that there are no other measures except for the oxide film on both poles.

Its electrical properties are similar to those with polarity, and have the characteristics of small volume and large capacity. The capacitance error, loss tangent, DC leakage current and other indicators are similar to those of ordinary polar electrolytic capacitors. It is mainly used in the polarity conversion of DC or pulse circuit, such as color TV decoding circuit. At present, many manufacturers in China have this kind of capacitor (different series, different electrical performance indicators).

2) A non-polar aluminum electrolytic capacitor used for frequency division in audio circuits.

This is a special type of non-polar electrolytic capacitor,

it is different from the general non-polar electrolytic capacitor, the volume is slightly larger than the general type, the electrical performance index is also higher than the general type,

the capacitance error is small, the loss is low, and the DC leakage current is small.

As a frequency dividing capacitor, most of them are used at the frequency of 10-20KHZ. The frequency characteristics of wound electrolytic capacitors are also very important.

WEE Technology Company Limited - WEE are Capacitors Specialist

Is there any difference between ordinary electrolytic capacitor and audio frequency electrodeless bi-polarized and non-polarized capacitor?

Can the capacitance of loudspeaker treble be replaced by ordinary electrolytic capacitor? Is it different from that of audio frequency electrodeless capacitor?

The difference is that ordinary electrolytic capacitors have positive and negative polarity requirements, and can only work at lower frequencies.

However, the electrodeless bi-polarized and non-polarized capacitors of loudspeakers have no polarity requirements and can work at relatively high frequencies, such as 1KHz or 100Hz.

If you need them in emergency, you can connect the two same electrodes of two common electrolytic capacitors together, and the other two terminals are used as the two poles of the combined capacitor

WEE Technology Company Limited - WEE are Capacitors Specialist

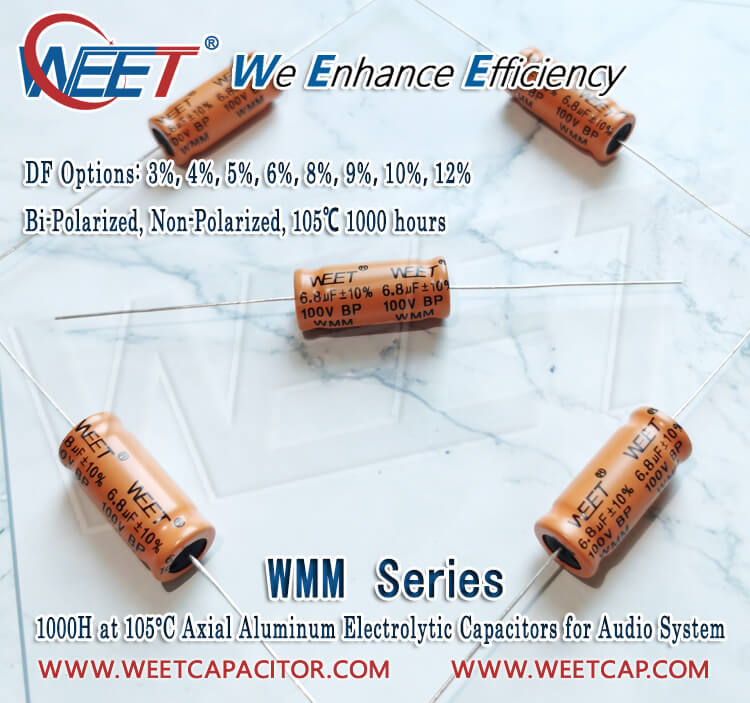

WMM 1000H 105°C, Bi-polar Alcap Features:

Low Dissipation Factor, MAX 5% at 1KHz

Specially produced for Cross-Over Networks with high fidelity audio system

High-quality crossover non-polar aluminum electrolytic capacitors

Product mainly used: audio converters and dividers (partials), Audio amp, automotive electronics products, speaker.

Note 1:Other Dissipation Factor 3%, 4%, 6%, 7%, 8%, 9%, 10%, 12% are available on request.

Note 2:The sleeve (PET) color of the product differs from batch to batch, so there will be slight color difference. Thank you.

No | Description | Dimension |

| WMM : 1000H 105°C, Bi-polar 1KHZ DF 5% Aluminum Electrolytic Capacitors for Audio and Speaker System | ||

| 1 | 4.7uF 50VDC +/-5% DxL=10*19mm Bulk RoHS | 10*19(D+0.5max,L+1.5max) |

| 2 | 6.8uF 50VDC +/-5% DxL=10*24mm Bulk RoHS | 10*24(D+0.5max,L+1.5max) |

| 3 | 8.2uF 50VDC +/-5% DxL=13*27mm Bulk RoHS | 13*27(D+0.5max,L-1+2max) |

| 4 | 10UF 50VDC +/-5% DxL=13*27mm Bulk RoHS | 13*27(D+0.5max,L-1+2max) |

| 5 | 15uF 50VDC +/-5% DxL=13*27mm Bulk RoHS | 13*27(D+0.5max,L-1+2max) |

| 6 | 22uF 50VDC +/-5% DxL=13*27mm Bulk RoHS | 13*27(D+0.5max,L-1+2max) |

| 7 | 33uF 50VDC +/-5% DxL=13*32mm Bulk RoHS | 13*32(D+0.5max,L-1+2max) |

| 8 | 47uF 50VDC +/-5% DxL=13*32mm Bulk RoHS | 13*32(D+0.5max,L-1+2max) |

| 9 | 68uF 50DC +/-5% DxL=16x34mm Bulk RoHS | 16*34(D+0.5max,L-1+2max) |

| 10 | 100UF 50VDC +/-5% DxL=16*34mm Bulk RoHS | 16*34(D+0.5max,L-1+2max) |

| 11 | 4.7uF 100VDC +/-5% DxL=13*27mm Bulk RoHS | 13*27(D+0.5max,L-1+2max) |

| 12 | 6.8uF 100VDC +/-5% DxL=13*27mm Bulk RoHS | 13*27(D+0.5max,L-1+2max) |

| 13 | 8.2uF 100VDC +/-5% DxL=13*27mm Bulk RoHS | 13*27(D+0.5max,L-1+2max) |

| 14 | 10UF 100VDC +/-5% DxL=13*27mm Bulk RoHS | 13*27(D+0.5max,L-1+2max) |

| 15 | 15uF 100VDC +/-5% DxL=13*27mm Bulk RoHS | 13*27(D+0.5max,L-1+2max) |

| 16 | 22uF 100VDC +/-5% DxL=13*27mm Bulk RoHS | 13*27(D+0.5max,L-1+2max) |

| 17 | 33uF 100VDC +/-5% DxL=13*32mm Bulk RoHS | 13*32(D+0.5max,L-1+2max) |

| 18 | 47uF 100VDC +/-5% DxL=13*32mm Bulk RoHS | 13*32(D+0.5max,L-1+2max) |

| 19 | 100UF 100VDC +/-5% DxL=16*38mm Bulk RoHS | 16*38(D+0.5max,L-1+2max) |

WEE Technology Company Limited - WEE are Capacitors Specialist

5. Open circuit

The open circuit failure of aluminum electrolytic capacitor may occur when it works in high temperature or hot humid environment for a long time. The reason is that the anode lead-out foil is broken due to electrochemical corrosion. For high voltage and large capacity capacitors, there are many such failure modes. In addition, if the anode lead-out foil and anode foil are riveted, the capacitor will open intermittently due to poor contact. In use, over mechanical stress may cuase the open circuit of the capacitor.

6. Deterioration of electrical parameters

① Decrease of capacitance and increase of loss

The capacitance of aluminum electrolytic capacitor decreases slowly in the early stage of operation, which is due to the continuous repair of working electrolyte and thickening of anodic oxide film during the loading process. In the later stage of use of aluminum electrolytic capacitor, due to the loss of electrolyte and the thickening of solution, the resistivity increases due to the increase of viscosity, resulting in the increase of equivalent series resistance of working electrolyte, resulting in the obvious increase of capacitor loss. At the same time, the electrolyte with increased viscosity is difficult to fully contact the oxide film on the surface of the corroded uneven aluminum foil, which makes the effective area of the electrode plate of the aluminum electrolytic capacitor decrease and the capacitance drops sharply. This is also the performance of the capacitor near the end of its service life.

In addition, if the viscosity of working electrolyte increases too much at low temperature, the loss will increase and the capacitance will drop sharply. In use, over temperature and ripple current may make the capacitance decrease and loss increase.

② Leakage current increases

The increase of leakage current often leads to the failure of aluminum electrolytic capacitor. Low process level, serious damage and contamination of oxide film, poor formulation of working electrolyte, low purity of raw materials, difficulty in long-term stability of chemical and electrochemical properties of electrolyte, low purity of aluminum foil and high content of impurities, etc., all of these factors may cause leakage current out of tolerance. The chloride ion contamination in aluminum electrolytic capacitor is serious. The leakage current leads to the decomposition of oxide film at the contaminated part, resulting in perforation, which further increases the current. In a word, the existence of metal impurities in aluminum foil will increase the leakage current of aluminum electrolytic capacitor, thus shortening the life of capacitor.

WEE Technology Company Limited - WEE are Capacitors Specialist

Today we will go on the topic about Aluminum Electrolytic Capacitors failure mode and cause analysis

3. Break down

The breakdown of aluminum electrolytic capacitor is caused by the rupture of anodic alumina dielectric film, which leads to direct contact between electrolyte and anode. The alumina membrane may be locally damaged due to various materials, processes or environmental conditions. Under the action of external electric field, the oxygen ion supplied by working electrolyte can form oxide film again at the damaged part, which makes the anodic oxide film filled and repaired. However, if there are impurity ions or other defects in the damaged parts, so that the filling and repairing work can not be completed, then there will be micro holes on the anodic oxide film, or even become through holes, which will make the aluminum electrolytic capacitor breakdown.

In addition, with the increase of use and storage time, the solvent in the electrolyte is gradually consumed and volatilized, which makes the acid value of the solution increase, and the oxidation film is corroded during storage. At the same time, due to the aging and drying up of electrolyte, oxygen ion can not be provided to repair the oxide film under the action of electric field, thus the self-healing effect is lost. Once the oxide film is damaged, the capacitor will be broken down. The process defect is also a main reason for the breakdown of aluminum electrolytic capacitor. If the riveting process is not good, the burr on the lead-in chaff will seriously hurt the oxide film, and the leakage current of the stabbed part is very large, and the local overheating will cause thermal breakdown of the capacitor. In use, over temperature, ripple current or mechanical stress may make the capacitor breakdown failure.

4. Burn down

The burning of aluminum electrolytic capacitor is generally caused by the following reasons:

① The positive and negative poles are reversed. Aluminum electrolytic capacitor is a kind of capacitor with positive and negative electrodes. If the positive and negative electrodes are wrongly connected when installing the aluminum electrolytic capacitor, the capacitor will burn out;

② The pressure is not enough. When the voltage exceeds the withstand voltage value of aluminum electrolytic capacitor, the capacitor will burn out;

③ The quality is unqualified. The aluminum electrolytic capacitors produced by some manufacturers are not up to standard, which may lead to the burning of capacitors.

WEE Technology Company Limited - WEE are Capacitors Specialist

WEET is famous in producing all kinds of aluminum electrolytic capacitors. Today we would like to share 6 failure modes and cause analysis about aluminum electrolytic capacitor. All the information is collected by WEET engineers and for knowledge reference only. If you have other opinions, welcome to email us and discuss with WEET engineers.

1、 Concept of aluminum electrolytic capacitor

Aluminum electrolytic capacitor is made of aluminum cylinder as negative electrode, which is filled with liquid electrolyte and inserted into a bent aluminum strip as positive electrode. It also needs DC voltage treatment to form an oxide film on the positive plate. It is characterized by large capacity, but large leakage, poor stability, positive and negative polarity, suitable for power filter or low-frequency circuit.

2、 Common failure modes of aluminum electrolytic capacitors

When the capacitor fails, the material, structure, manufacturing process, performance and service environment of all kinds of capacitors are different, and the failure mechanism is also different. Today, easy capacity network will reveal common failure modes of aluminum electrolytic capacitors: leakage, explosion, open circuit, breakdown, deterioration of electrical parameters, etc.

3、 Failure mode and cause analysis

A. Leakage

Leakage is one of the causes of capacitor failure, and aluminum electrolytic capacitor is no exception. The working electrolyte of aluminum electrolytic capacitor is acidic. If it overflows, it will seriously pollute and corrode other components and printed circuit board around the capacitor. At the same time, the electrolyte in the electrolytic capacitor dries up gradually due to leakage, which leads to the failure of capacitor due to breakdown or deterioration of electrical parameters. There are many causes of leakage, such as:

① The sealing of aluminum electrolytic capacitor is poor;

② If the aluminum electrolytic capacitor is sealed with rubber plug, the rubber may be aged and cracked due to its long service life;

③ There are some problems in mechanical seal technology;

④ Generally, the manufacturer will consider the problem of liquid leakage. They will specify in the enterprise standard that vertical installation is required, while some enterprises adopt horizontal installation.

B. Explosion

When the working voltage of aluminum electrolytic capacitor is too large, or there are many defects in the oxide film medium, or there are harmful anions such as chlorine radical and sulfate radical, so that when the leakage current is large, the rate of gas generated by electrolysis is faster. The longer the working time is, the greater the leakage current, the more gas in the shell and the higher the temperature. The pressure difference inside and outside the metal shell of capacitor will increase with the increase of working voltage and working time. If the sealing is good and there is no explosion-proof measures, the capacitor will explode when the air pressure increases to a certain extent.

WEE Technology Company Limited - WEE are Capacitors Specialist

The positive and negative polarity will be marked on the shell of electrolytic capacitor, and attention must be paid to its polarity in actual use, otherwise there is a risk of explosion. If the polarity of an electrolytic capacitor can not be recognized, its polarity can be judged with a pointer multimeter.

So how to identify the polarity of Electrolytic capacitor by Multimeter?

Due to the difference between positive and negative polarity of electrolytic capacitor, it has a feature of using multimeter resistance to detect it: the positive electrode is connected with black probe (positive power supply), the negative terminal is connected with red probe (negative power supply), and the leakage current of electrolytic capacitor is small (Large leakage resistance). On the contrary, the leakage current of electrolytic capacitor increases (the leakage resistance decreases).

When measuring, first assume that one pole is "+" pole, connect it with the black probe of the multimeter, and connect the other electrode with the red probe of the multimeter. Record the scale of the stop of the probe (the resistance value of the probe is large on the left side), then discharge the capacitor (i.e. the two leads touch each other), exchange the two probes, and re measure. In the two measurements, the last time the needle stays on the left (with high resistance), the black probe is connected to the positive electrode of the electrolytic capacitor.

At the same time, you can tell the polarity of WEET Axial Electrolytic capacitors by external appearance. Firstly, on one side of the lead, there is a protruding end, which is a negative pole. At the same time, the sleeve marking will has a "-" one it and arrow to one side , which is showing as negative pole.

WEE Technology Company Limited - WEE are Capacitors Specialist

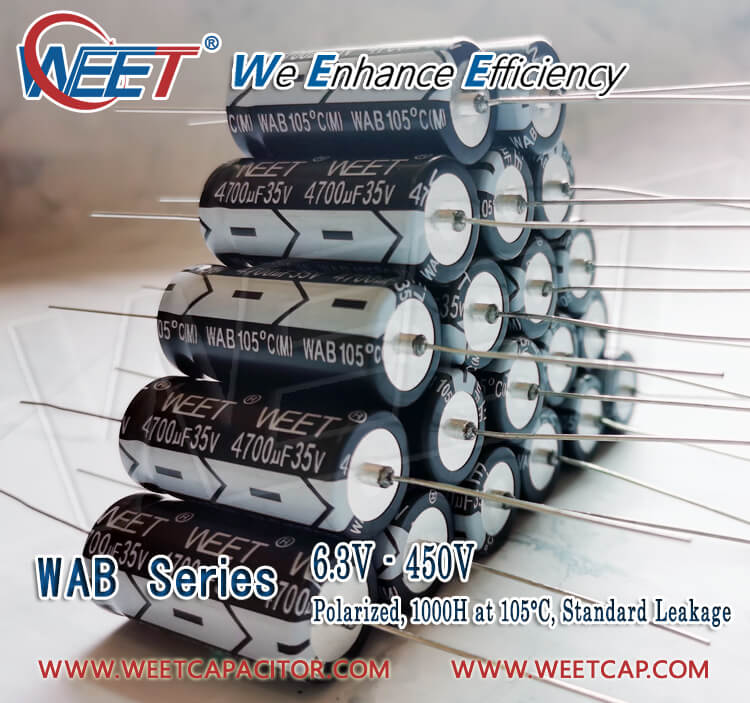

The main applications of the polarized axial Aluminum Electrolytic Capacitors products are: frequency converter, frequency conversion air conditioner, welding machine, inverter power supply, switching power supply, high-quality electronic machine, high-grade audio frequency division, computer motherboard, intelligent instrument, power wave of industrial control equipment, medical equipment, household appliances, communication power supply, etc...

Widely used in smart meters, electric vehicle charger controller, car navigation box, vehicle electronic equipment, POS card reader, smart meter, TV set-top box, satellite receiver, VCD / DVD, audio amplifier, car audio, charger, telephone, instrument, electronic ballast, electronic energy-saving lamps, lighting, financial equipment and appliances, medical electronic equipment and other electronic equipment Products.

WEE Technology Company Limited - WEE are Capacitors Specialist

WEET WMS - Non-Polarized 1000H at 105°C, DF at Max 10% BP Axial Aluminum Electrolytic Capacitors for Audio Applications

Below is WMS hot and common capacitance, free samples on request, welcome to contact with WEET capacitor.

| 1μF 100VDC +/-10% D*L: 8*17mm |

| 1.5μF 100VDC +/-10% D*L: 8*18mm |

| 2.2μF 100VDC +/-10% D*L: 8*18mm |

| 2.7μF 100VDC +/-10% D*L: 8*18mm |

| 3.3μF 100VDC +/-10% D*L: 8*18mm |

| 3.9μF 100VDC +/-10% D*L: 8*18mm |

| 4.7μF 100VDC +/-10% D*L: 10*19mm |

| 5.6μF 100VDC +/-10% D*L: 10*20mm |

| 6.8μF 100VDC +/-10% D*L: 10*20mm |

| 8.2μF 100VDC +/-10% D*L: 10*20mm |

| 10μF 100VDC +/-10% D*L: 10*20mm |

| 12μF 100VDC +/-10% D*L: 10*20mm |

| 15μF 100VDC +/-10% D*L: 10*20mm |

| 18μF 100VDC +/-10% D*L: 10*20mm |

| 22μF 100VDC +/-10% D*L: 10*24mm |

| 27μF 100VDC +/-10% D*L: 13*27mm |

| 33μF 100VDC +/-10% D*L: 13*27mm |

| 39μF 100VDC +/-10% D*L: 13*27mm |

| 47μF 100VDC +/-10% D*L: 13*27mm |

| 56μF 100VDC +/-10% D*L: 13*32mm |

| 68μF 100VDC +/-10% D*L: 13*32mm |

| 82μF 100VDC +/-10% D*L: 16*34mm |

| 100μF 100VDC +/-10% D*L: 16*34mm |

| 120μF 100VDC +/-10% D*L: 16*34mm |

| 150μF 100VDC +/-10% D*L: 16*34mm |

| 220μF 100VDC +/-10% D*L: 18*44mm |

| 270μF 100VDC +/-10% D*L: 18*44mm |

| 300μF 100VDC +/-10% D*L: 18*44mm |

| 330μF 100VDC +/-10% D*L: 22*44mm |

WEE Technology Company Limited - WEE are Capacitors Specialist

Do you know, why Axial Aluminum Electrolytic Capacitors must know the polarity? The capacitance of the capacitor is inversely proportional to the square of the distance between the two electrodes and is proportional to the area. The polarity of electrolytic capacitor is determined by the characteristics of its medium (insulator). The medium of electrolytic capacitor is metal oxide film, that is, the electrolytic (DC) process forms an oxide film on the surface of aluminum foil. Because the oxide film is very thin, the capacity of electrolytic capacitor can be very large. If the polarity of the capacitor is reversed, the electrolytic film will be destroyed under the reverse voltage, and the capacitor will fail. Therefore, the electrolytic capacitor has polarity.

WEET WAA 85°C, Low Leakage, 2000 Hours , Polarized Axial Aluminum Electrolytic Capacitor Common Items are as below. WEET is the earliest Polarized Axial Aluminum Electrolytic Capacitor factory in China.

| WAA - 85°C, Low Leakage, 2000 hours , Axial Aluminum Electrolytic Capacitor | Dimension: OD*L (mm) |

| WAA 10uF 160V +/-20% Bulk RoHS* | 10*17 |

| WAA 100uF 100V +/-20% Bulk RoHS* | 13*22 |

| WAA 100uF 35V +/-20% Bulk RoHS* | 8*16 |

| WAA 100uF 63V +/-20% Bulk RoHS* | 10*17 |

| WAA 220uF 100V +/-20% Bulk RoHS* | 16*28 |

| WAA 220uF 35V +/-20% Bulk RoHS* | 10*17 |

| WAA 330uF 25V +/-20% Bulk RoHS* | 10*17 |

| WAA 330uF 35V +/-20% Bulk RoHS* | 10*21 |

| WAA 330uF 63V +/-20% Bulk RoHS* | 13*22 |

| WAA 4.7uF 160V +/-20% Bulk RoHS* | 8*16 |

| WAA 47uF 100V +/-20% Bulk RoHS* | 10*21 |

| WAA 470uF 100V +/-20% Bulk RoHS* | 16*36 |

| WAA 470uF 25V +/-20% Bulk RoHS* | 10*21 |

| WAA 470uF 25V +/-20% Bulk RoHS* | 10*21 |

| WAA 470uF 63V +/-20% Bulk RoHS* | 13*27 |

| WAA 470uF 63V +/-20% Bulk RoHS* | 13*27 |

| WAA 22uF 100V +/-20% Bulk RoHS* | 8*16 |

| WAA 220uF 25V +/-20% Bulk RoHS* | 8*16 |

| WAA 220uF 63V +/-20% Bulk RoHS* | 13*22 |

| WAA 33uF 63V +/-20% Bulk RoHS* | 8*13 |

| WAA 330uF 100V +/-20% Bulk RoHS* | 16*33 |

| WAA 47uF 63V +/-20% Bulk RoHS* | 8*16 |

| WAA 1uF 100V +/-20% Bulk RoHS* | 5*12 |

| WAA 1uF 63V +/-20% Bulk RoHS* | 5*12 |

| WAA 1uF 100V +/-20% Bulk RoHS* | 5*12 |

| WAA 1uF 350V +/-20% Bulk RoHS* | 8*16 |

| WAA 1uF 63V +/-20% Bulk RoHS* | 5*12 |

| WAA 10uF 25V +/-20% Bulk RoHS* | 5*12 |

| WAA 10uF 63V +/-20% Bulk RoHS* | 5*12 |

| WAA 10uF 35V +/-20% Bulk RoHS* | 5*12 |

| WAA 10uF 350V +/-20% Bulk RoHS* | 13*22 |

| WAA 10uF 63V +/-20% Bulk RoHS* | 6.3*13 |

| WAA 100uF 16V +/-20% Bulk RoHS* | 6.3*13 |

| WAA 100uF 25V +/-20% Bulk RoHS* | 8*13 |

| WAA 100uF 350V +/-20% Bulk RoHS* | 22*40 |

| TS13AH 2.2uF 50V +/-20% Bulk RoHS* | 5*12 |

| TS13AH 3.3uF 50V +/-20% Bulk RoHS* | 5*12 |

| WAA 2.2uF 100V +/-20% Bulk RoHS* | 5*12 |

| WAA 2.2uF 350V +/-20% Bulk RoHS* | 10*17 |

| WAA 2.2uF 63V +/-20% Bulk RoHS* | 5*12 |

| WAA 2.2uF 63V +/-20% Bulk RoHS* | 5*12 |

| WAA 22uF 16V +/-20% Bulk RoHS* | 5*12 |

| WAA 22uF 25V +/-20% Bulk RoHS* | 6.3*13 |

| WAA 22uF 35V +/-20% Bulk RoHS* | 6.3*13 |

| WAA 22uF 350V +/-20% Bulk RoHS* | 13*27 |

| WAA 3.3uF 63V +/-20% Bulk RoHS* | 5*12 |

| WAA 33uF 350V +/-20% Bulk RoHS* | 16*33 |

| WAA 4.7uF 350V +/-20% Bulk RoHS* | 10*21 |

| WAA 4.7uF 63V +/-20% Bulk RoHS* | 5*12 |

| WAA 4.7uF 100V +/-20% Bulk RoHS* | 6.3*13 |

| WAA 4.7uF 63V +/-20% Bulk RoHS* | 5*12 |

| WAA 47uF 16V +/-20% Bulk RoHS* | 6.3*13 |

| WAA 47uF 25V +/-20% Bulk RoHS* | 6.3*13 |

| WAA 47uF 35V +/-20% Bulk RoHS* | 6.3*13 |

| WAA 47uF 350V +/-20% Bulk RoHS* | 16*40 |

![]()