Where can we buy axial resistor at a great price online? Definitely from China's WEET factory! We provide you with the best experience throughout, whether it's product quality or after-sales service.

Now, let WEET introduce our product: 1W 1K OHM CF Series Axial Resistor.

FEATURES:

Operating Temp. Range: -55℃~ +155℃.

Tolerance Specifications: Standard tolerance of ±2% and ±5%.

Stability: Exceptional long-term stability, exceeding the performance standards of MIL-R-11 carbon composition resistors.

Packaging Options: Flexible packaging solutions available, including bulk, strip pack, 26mm tape and reel, and 52mm tape and reel.

APPLICATIONS:

Industrial Control Equipment.

Consumer Electronics.

Automotive Electronics.

Telecommunications Equipment.

Medical Devices.

Power Supply Units.

More Details:https://www.resistorsfactory.com/Axial-Resistors/WEET-CF-Series-Carbon-Film-Resistor.html

More Informations:https://www.resistorsfactory.com/Applications/WEET-Resistors-in-Automotive-Applications.html

If you need axial resistor, feel free to contact us!

Contact Information:Sales@weetcap.com

WEE Technology Published on Nov 11, 2025

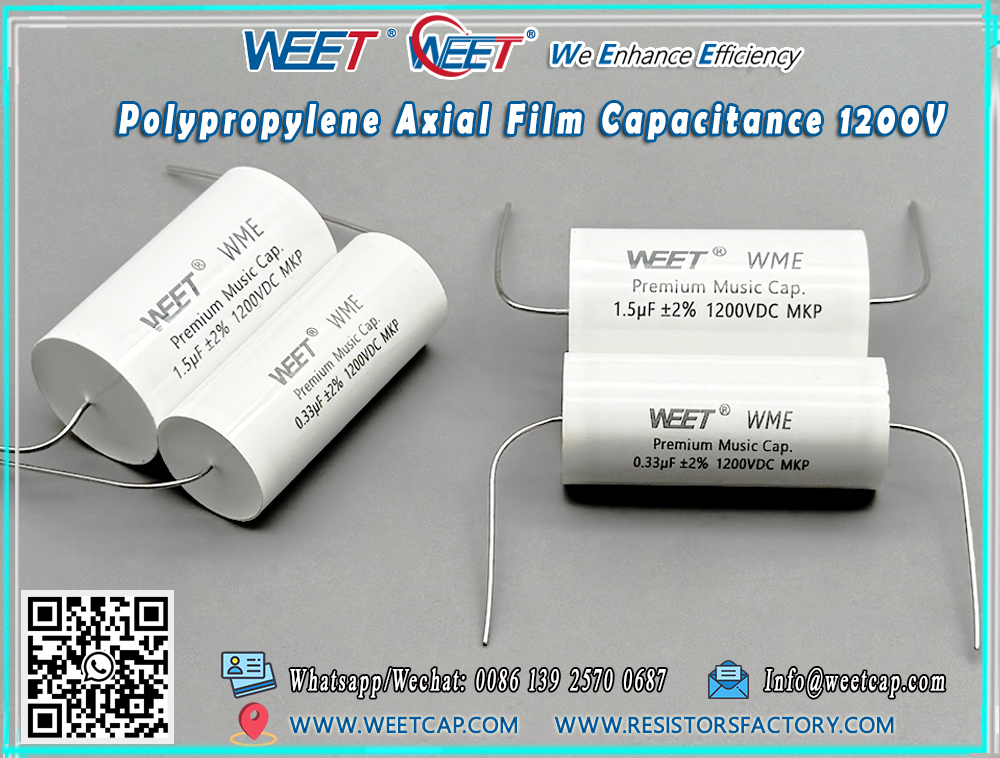

Today, I would like to introduce an audio capacitor - WEET WME 1200V 0.22uF Metallised Polypropylene, which is used in crossovers and speakers.

Some details about the Polypropylene Axial Film Capacitance 1200V:

Capacitance range: 0.22uF.

Operating temperature: -55℃~+85℃.

Capacitance tolerance: ±5%.

Rated voltage: 1200VDC.

Leads Diameter: 0.8, 1.0 Tinned Pure Copper Wire.

This is the primary application field of audio film capacitors, which directly affects sound quality performance:

Crossovers: As the "core component" of a crossover.

Power amplifiers.

Preamplifiers.

Notes:

WEET WME Metallised Polypropylene 1200V 0.22uF can replace Silver Z-Cap 001-0610.

WEET WME 1250V adopts a series structure and is combined with PP plain film, thus enabling high-voltage performance.

Contact us:Wallis@weetcap.com

WEE Technology Published on Sept 1, 2025

To meet the demands of audiophiles, while pursuing high quality and ensuring an attractive price point, the WMT gold-plated copper leads capacitor and WMF Metallized Polypropylene Film capacitor were thus developed.

Specifications:

| Audio Capacitor | WMT Capacitor | WMF Capacitor |

| Operating temperature | -55℃~+85℃ | -55℃~+85℃ |

| Rated voltage | 50V、100V、250V、400V、630V.DC | 250V、400V、630V.DC |

| Leads Diameter | 0.8、1.0 Pure Silver/Gold Tinned Copper Wire | 0.8、1.0 Tinned Pure Copper Wire |

Size Table:

| 250V 5.6uF | OD | L | d | LL |

| WMT, WMF Capacitor | 22.5 | 31.5 | 0.8 | 38 |

Click here to find more information:

WMT Silver Gold Tinned Copper Wire Condenser Audio Grade capacitor PDF

WMF Precise Audiophiler Metallized Polypropylene Film capacitor PDF

Notes:

WEET Audio Capacitors with our price advantage and product quality, can replace ERSE, Mundorf - MCAP MKP, Mallory, BENNIC, Auricap, Ampohm audio series.

Contact us:Wallis@weetcap.com

WEE Technology Published on Aug 29, 2025

Are you still looking for capacitors? Today, I will introduce two types of audio capacitors 12uF, which may be exactly what you need.

Audio Grade WMT Capacitors Gold Tinned Copper Wire and Precise Audiophiler WMF Film Capacitor.

These two capacitors are similar and share many common features and applications.

They all,

Quick transient design.

Very Low Dielectric absorption factor.

Excellent handling of high current audio pulses.

Very Low Dissipation factor, Very Low ESR, Very Low Inductance.

Used in the audio field.

But the differences is Rated Voltage:

WMT Silver Gold Tinned Copper Wire Capacitor Rated voltage: 50V、100V、250V、400V、630V.DC

WMF Precise Audiophiler film Capacitor Rated voltage: 250V、400V、630V.DC

Notes:

WEET audio capacitors can replace Mallory, ERSE, Mundorf - MCAP MKP, BENNIC, SCR / SOLEN, Auricap, INTERTECHNIK, Ampohm audio series.

Special attention should be paid to the fact that the gold-plated copper leads provide long-term high reliability and excellent solder ability.

Find more information:

WEET WMT Silver Gold Tinned Copper Wire Condenser Audio Grade MKP Capacitors

WEET WMF Precise Audiophiler MKP Metallized Polypropylene Film Capacitor Low DF

Contact us:Wallis@weetcap.com

WEE Technology Published on Aug 28, 2025

Their service life is typically quite long; however, how can one determine if they are aging?

Most Intuitive Method: Listen for Sound Quality Changes:

Loss of High-Frequency Details: The tweeter output becomes vague or inaudible, and the overall sound turns "dull and unclear."

Distortion or Noise: When playing music, there is a "muffled texture," "hissing sound," or irregular noise.

Crossover Misalignment.

Recommendations for Extending Service Life:

Prioritize audio-specific polypropylene film capacitors.

Keep the speaker away from high-temperature and humid environments.

Ensure the capacitor parameters match those of the crossover.

Summary:

Need Film caps for audio amps? Contact us for details! Hesitant? We can send free samples to prove trusting us is right!

WEET WME MKP Axial film Cap can replace Audyn Cap, and WEET WME MKP axial film capacitors are smaller in size than Audyn Cap QS4.

| WEET Item | Replacement | |

| 4000V | MKP 0.33uF 400V 5% | 400 VDC 5% Axial Order - No. 1341260 |

| MKP 1.5uF 400V 5% | 400 VDC 5% Axial Order - No. 1341310 | |

| 600V | MKP 0.33uF 600V 2% | 600 VDC 2% Axial Order - No. 1501152 |

| MKP 1.5uF 600V 2% | 600 VDC 2% axial Order - No. 1501159 | |

| 800V | MKP 10uF 800V 2% | 800 VDC 2% Axial Order - No. 1341766 |

| 1200V | MKP 0.33uF 1200V 2% | 1200 VDC 2% Axial Order - No. 1341754 |

| MKP 1.5uF 1200V 2% | 1200 VDC 2% Axial Order - No. 1341759 | |

Click the link to view details:WEET Axial Capacitor For Filter Out Noise

Contact us:Wallis@weetcap.com

WEE Technology Published on Aug 22, 2025

You know What Type of Capacitor Is Best For Speaker Crossover? If you don’t, maybe this article can be helpful to you.

Best Choices For Different Scenarios:

| Best capacitor for tweeter crossover (Low Distortion, High Detail) | Polypropylene (MKP) Film Capacitors, Extremely sensitive to loss and distortion. |

| Midrange Crossover (Balance Loss & Cost) | 1. MKP Film Capacitors (Priority) 2. Metallized Film Capacitors (MKT) (Budget-Limited). |

| Woofer Crossover (Large Capacity, Low Cost) | 1. Non-Polarized Electrolytic Capacitors (High Capacity Needed) 2. MKP Film Capacitors (Bass Texture Priority). |

| Audiophile/High-End Speakers (Ultimate Sound Quality) | 1. Polystyrene (PS) Film Capacitors (Small-Capacity High Frequencies) 2. MKP Film Capacitors (Medium-to-Large Capacities). |

Summary:

WEET MKP WME Speaker crossover capacitor upgrade can replace Audyn Cap.

MKP 0.33uF 600V 2% can replace Audyn Cap Tri-Reference 0.33 uF - 600 VDC 2% axial 25x50 Order-No.1501152

MKP 1.5uF 600V 2% can replace Audyn Cap Tri-Reference 1.50 uF - 600 VDC 2% axial 35x60 mm Order-No.1501159

Searching for further information: WME MKP Axial Capacitor For Filter Out Noise.

WEE Technology Published on Aug 21, 2025

Today, WEET would like to introduce to you a product that can replace the Audyn Cap Plus - WEET WME 800V axial MKP capacitor.

Features:

The capacitance range is 0.1μF ~ 100μF, and the rated voltages are 50V, 100V, 250V, 400V, and 630V.

Fast transient design with high-precision capacitance tolerances of ±1%, ±2%, ±3%, and ±5%.

Extremely low dissipation factor, extremely low dielectric absorption factor, extremely low ESR (Equivalent Series Resistance), and extremely low inductance.

Applications:

WEET WME MKP premium polypropylene music precision audio low DF (Dissipation Factor) film audiophile-grade capacitors, suitable for frequency dividers and speakers.

Capacitors used in passive loudspeaker crossovers. Audio-grade capacitors, audiophile MKP, Hi-Fi audio MKP capacitors, polypropylene film.Bipolar audio crossover capacitor amplifier modules.Non-polarized metallized polypropylene crossover capacitors.

Notes:

Our 800V axial capacitor for power supply offer a more favorable price and a smaller size.

WEET MKP 10uF 800V 2% can replace AUDYN CAP PLUS MKP 10.0 MF/800V 2% Axial 68X35 Order-No. 1341766.

Contact us:Wallis@weetcap.com

Click on the image to view detailed information:

(Bouble Winded)

WEE Technology Published on Aug 20, 2025

Which capacitors used in passive loudspeaker crossovers? That is our MKP WME capacitor.

What materials is Polypropylene Axial Film Capacitance 1200V mainly composed of?

Core dielectric material: Polypropylene film, which serves as the insulating medium of the capacitor.

Electrode material: Aluminum, which acts as the electrode of the capacitor.

Lead-out terminal material: The electrode is led out via tinned copper wire, and the (encapsulation) is filled with 94V-0 epoxy resin.

Summary:

WEET WME film caps for audio amps Can Replace Audyn Cap QS4. Our MKP capacitors are smaller in size than theirs, making them easier to install.

WEET MKP 0.33uF 1200V 2% Replace Audyn 1200V 2% AXIAL 0.33 MF Order-No. 1341754.

WEET MKP 1.5uF 1200V 2% Replace Audyn 1200V 2% AXIAL 1.50 MF Order-No. 1341759.

Detail information:https://weetcap.com/pdf/WEET-WME-Premium-Music-Capacitors-Crossover-HIFI-Audio-Application-Polypropylene-Film-Capacitor.pdf

Contact us:Wallis@weetcap.com

Double Winded

WEE Technology Published on Aug 19, 2025

Today, I'd like to introduce to you a capacitor specifically designed for audio applications – MKP WME Premium Metallized Polypropylene Axial Film Capacitance (400V).

WEET WME MKP axial capacitor for filter out noise, is composed of a combination of vacuum-metallized aluminum polypropylene film, which serves as both the dielectric and the electrode.

The electrodes are led out via tinned copper wires and encapsulated with 94V-0 epoxy resin.

Specifications:

| Series | WME |

| Capacitance range | 0.1~100uF |

| Operating temperature | 55℃~+85℃ |

| Capacitance tolerance | ±1%, ±2%, ±3%, ±5% 1KHz |

| Rated voltage | 50V, 100V, 250V, 400V, 630V.DC |

Notes:

MKP 0.33uF 400VDC replaces Audyn 400 VDC 5% Axial Order-No. 1341260

MKP 1.5uF 400VDC replaces Audyn 400 VDC 5% Axial Order-No. 1341310

WEE Technology Published on Aug 18, 2025

Are you unsure about which High End Audio Grade Capacitor to buy? This article introduces Bypass Capacitor Audio-MKP for you.

HiFi Axial Fever Crossover Coupling Capacitor, is a type of capacitor specifically designed and optimized for high-end audio equipment.

Features:

Low distortion.

Low loss.

High voltage resistance.

Application Fields:

Home Hi-Fi systems.

High-end car audio systems.

Hi-Res DAPs (High-Resolution Digital Audio Players).

High-end radios and turntables

Summary:

WEET, one of the best audio bypass capacitor brands. To meet customer needs, the leads of the product are extended to 100mm, 3% capacitance tolerance.

In terms of cost-effectiveness, our product can be a replacement for Mundorf MCap EVO Oil, and the 100μF model can replace their MEO-68T3.350.

For detailed information, please click the link: MKP Metallized Polypropylene Film Capacitor Low DF.

WEE Technology Published on Aug 15, 2025