Cement resistance has good heat resistance, low temperature coefficient, low noise, high load power, high insulation, and non flammability. Operating environment temperature: -55 ℃~+275 ℃

Cement resistors are usually used in situations with high power and current, including 2W, 3W, 5W, 10W, 15W, 20W, 25W, 30W, 50W, and even higher power. Cement resistors are commonly used in appliances with power levels above 100 watts, such as air conditioners and televisions.

The disadvantage of cement resistance lies in its large volume, high heat generation during use, difficulty in dissipating, and often insufficient precision to meet usage requirements, stability, etc. When high power, small volume resistors, or high precision and fast heat dissipation are required, cement resistors can be replaced with JEPSUN power resistors, which can achieve power of 3W, 20W, 30W, 50W, 100W, or even higher. TO-220 and TO-247 packaging are used, with high precision, strong stability, and fast heat dissipation.

Its advantages and disadvantages:

1. Features such as shock resistance, moisture resistance, heat resistance, good heat dissipation, and low price.

2. Completely insulated, suitable for printed circuit boards.

3. Wrap wires on the porcelain rod and then weld the joints to produce precise resistance values and extend the lifespan.

4. High resistance values are made using metal oxide film (MO) instead of wire winding.

5. Excellent heat resistance, low temperature coefficient of resistance, and linear variation.

6. Durable to short-term overload, low noise, resistance value remains unchanged over the years.

7. Good explosion-proof performance, providing protection.

WEE Technology Company Limited - WEE are Capacitors Specialist

We would like to say thank you in 2023 for all your support and cooperation with WEET.

May the glow of Christmas candle fill your heart with peace and pleasure and make your New Year bright. Have a love filled Christmas and New Year!

Best wishes from Your reliable supplier, WEE Technology Company Limited

1、 Cement Ceramic Resistor Product Introduction

Cement resistors are the earliest resistors used and widely used in various products.

They are the most basic electronic components in electronics, appliances, equipment, and information products.

It has characteristics such as small size, shock resistance, moisture resistance, heat resistance, good heat dissipation, and low price.

Cement resistance is fully insulated and suitable for printed circuit boards.

Cement resistance has excellent heat resistance, low resistance temperature coefficient, and a linear variation;

Short term overload resistance, low noise, resistance value unchanged over the years.

2、 Cement Ceramic Resistor Structure

A. Cement resistance is formed by winding resistance wire on a ceramic rod with good heat resistance or

a glass fiber substrate with insulation and heat dissipation, forming a wire wound resistance core.

After passing all tests, the wire wound resistance core is placed inside a ceramic shell of different sizes and shapes,

sealed with a special non combustible heat-resistant cement electronic filling material,

naturally dried in the shade and baked at high temperature.

B. High resistance specifications are made using metal oxide film resistor cores instead of wire wound resistor cores.

3、 Cement Ceramic Resistor Applicable scope

Widely used in AC and DC circuits such as electronics, appliances, power supplies, sound systems, and home appliances,

it is one of the most common ideal electronic components in electronic circuits

WEE Technology Company Limited is a marketing office established in Hong Kong since 2000.

Our resistor factory located in Dongguan province of China.

We are specialized in manufacturing, R&D, Production and Sales of SMD, Axial, Cement,

Audio and Power resistor products.

WEET factory are endowed with ISO 9001 quality management certifications.

All of our products are RoHS and REACH Compliance, superior quality with competitive price.

WEET is in full charges of supporting and handling all the affairs and business development

of the overseas customers from our mainland factories.

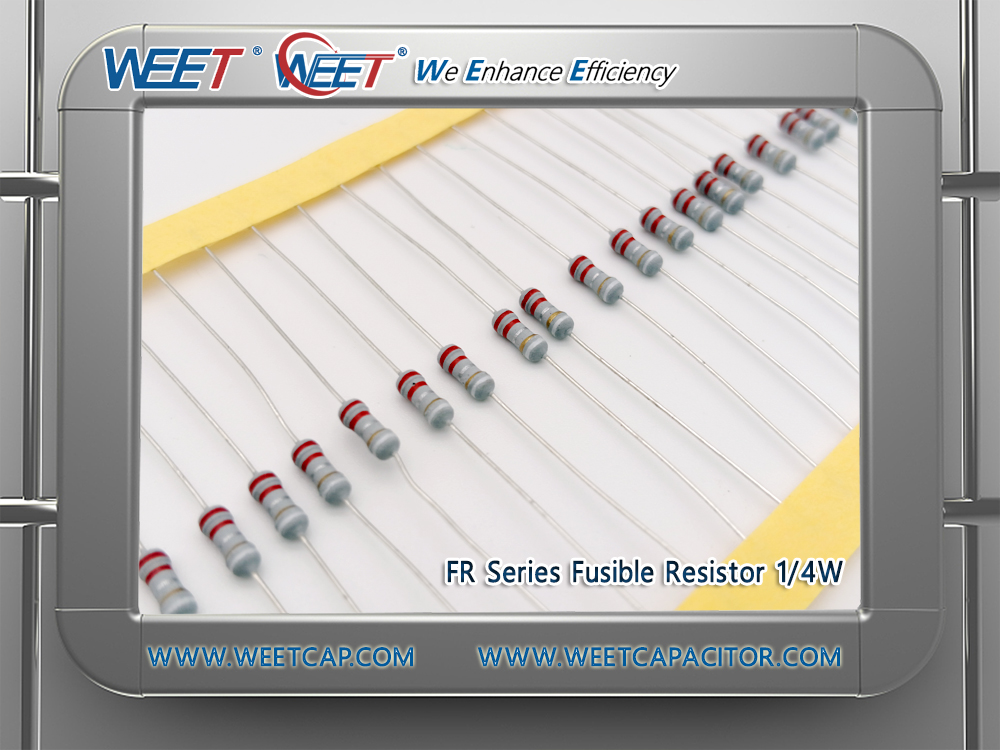

WEE Technology produces full range of series resistors, such as Carbon Film Resistor,

Metal Film Precision Resistor, Metal Oxide Resistor, Fusible Resistor,

Wire Wound Resistor, High Precision Metal Film Leaded Resistor,Metal Film Leaded Precision Resistor,

Precision Compact Size Resistor Networks (UPSC),

Jumper Wire Resistor, Low Value Wire Resistor, Metal Galazed Resistor, Melf Carbon Film Resistor,

Melf Metal Film Resistor, Cement Resistor, Ceramic Resistors,

Non-Flammable Wire-Wound Power Resistor, Aluminum Housed Wire Wound Resistor,

Metal Clad Wire Wound Resistor.

The resistors we produce are widely applied in Automotive Industry, Power Supply Industry,LED Lighting,

Home Appliances, Communication Equipment, electronic toys and other consumer goods,

Medical Equipment Industry, communication equipment, computers, automotive electronics,

high-frequency and microwave circuits,automotive electronics, power circuits, converters, regulators and other fields

https://www.resistorsfactory.com/product/

Dear Customers,

WEE Technology Company Limited will enjoy long holiday soon. Please find below time line. Thank you.

Mid-Autumn Festival and National Day Holiday : 29th Sept. to 8th Oct. 2023, resume work on 9th Oct. 2023

Welcome your enquiry at any time, we will reply as soon as we return to work.

Happy Holiday, thank you.

Best regards,

WEET Team

The manufacturing process of carbon film resistors utilizes carbon precipitation on magnetic rods or ceramic tubes,

forming a layer of carbon film crystals on their surface.

By adjusting the thickness of the carbon film and changing the degree of carbon film resistance through grooving,

we obtain the required resistance value and apply epoxy resin on the surface to strengthen the sealing.

The carbon film resistor is made into a color ring resistor series in appearance,

namely the color ring carbon film resistor; The resistance range of this type of color ring resistor is 1Ω~ 10MΩ,

Rated power includes 0.125W, 0.25W, 0.5W, 1W, etc.,

Accuracy range:± 10%,± 5%,± 2%,

this type of carbon film resistor is generally larger in volume and is often used in some inexpensive electronic products,

such as familiar mobile phone chargers, computer power supplies, and other electronic device circuits.

WEE Technology Company Limited - WEE are Capacitors Specialist

https://www.weetcap.com/Resistors/WEET-MO-Series-Metal-Oxide-Resistor.html

https://www.mundorf.com/audio/en/shop/Resistors/

High Power-to-Size ratio for significant space savings

Excellent long-term stability

Complete flameproof construction

High surge/overload capability

Wide Resistance range: 1Ω~180KΩ

Standard tolerance: ±1%, ±2%, ±5%

| MO Series Metal Oxide Resistor-5W | |||

| 0.10 Ohm | 1.2 Ohm | 4.7 Ohm | 18 Ohm |

| 0.22 Ohm | 1.5 Ohm | 5.6 Ohm | 22 Ohm |

| 0.33 Ohm | 1.8 Ohm | 6.8 Ohm | 27 Ohm |

| 0.47 Ohm | 2.2 Ohm | 8.2 Ohm | 33 Ohm |

| 0.68 Ohm | 2.7 Ohm | 10 Ohm | 39 Ohm |

| 0.82 Ohm | 3.3 Ohm | 12 Ohm | 47 Ohm |

| 1.0 Ohm | 3.9 Ohm | 15 Ohm | 56 Ohm |

Wire wound resistors are made by winding the resistance wire non-corrosive, heat-proof and humidity-proof material.

Delivery from stock in bulk taped, and strip pack.

Exceptional long-term stabiligy

Standard tolerance:±1%, ±2%, ±5%

| Power Rating 70℃ | KNP-1/2W | KNP-1W | KNP-2W | KNP-3W | KNP-4W | KNP-5W | KNP-7W | KNP-8W | KNP-10W |

| Series Number | KNS-1W | KNS-2W | KNS-3W | KNS-4W | KNS-5W | KNS-7W | KNS-10W | - | - |

| Operating Temp. Range | -55℃~ +155℃ | ||||||||

| Dielectric Withstanding Voltage(AC) | 500V | 500V | 500V | 500V | 500V | 500V | 500V | 800V | 1000V |

| Value Range ±5% | 0.1Ω-300Ω | 0.1Ω-499Ω | 0.1Ω-1.5KΩ | 0.1Ω-1.5KΩ | 0.1Ω-1.5KΩ | 0.5Ω-3KΩ | 0.5Ω-3KΩ | 1Ω-3KΩ | 1Ω-3KΩ |

| Temp. Coefficient (by Type) | ±350ppm/℃ | ||||||||

WEE Technology Company Limited - WEE are Capacitors Specialist

| Type | Rated power | Resistance range(Ω) | Tolerance | Max Wording | Max Overload |

| SQM | (w) | Wire wound | ±(%) | Voltage(V) | Voltage(V) |

| 1 | 0.1~1K | 1(F) | 150 | 500 | |

| 2 | 0.1~2K | 2(G) | 350 | 750 | |

| 3 | 0.1~3K | 5(J) | 500 | 1000 | |

| 5 | 0.1~5K | 10(K) | 750 | 1000 | |

| 7 | 0.1~10K | 1000 | 1500 | ||

| 10 | 0.1~10K | 1000 | 1500 | ||

| 10WS | 0.1~10K | 1000 | 1500 | ||

| 10WB | 0.1~10K | 1000 | 1500 | ||

| 15WS | 0.1~10K | 1000 | 1500 | ||

| 15 | 0.1~10K | 1000 | 1500 | ||

| 20 | 0.1~10K | 1000 | 1500 |

WEE Technology Company Limited - WEE are Capacitors Specialist

Ceramic insulated power type wire wound resistors are often referred to as cement resistors.

It is widely used in computers, televisions, instruments, instruments, and audio systems.

Cement resistors are wound with resistance wires, generally with high power and larger overall dimensions.

Therefore, it can be easily distinguished from its appearance, power, and model.

In terms of power, it is divided into specifications such as 2W, 3W, 5W, 7W, 8W, 10W, 15W, 30W, 20W, 40W, etc.

The common model is SQP cement resistor, which adopts an industrial high-frequency electronic ceramic shell, with good heat dissipation and excellent insulation performance.

Its insulation resistance can reach 100MR, and it also has excellent flame retardant and explosion-proof properties.

The resistance wire is made of alloy materials such as constantan, manganese copper, nickel chromium, etc., which have good stability and overload capacity.

The resistance wire is crimped with the solder lead wire. In the event of a load short circuit, it can quickly fuse at the crimping point, providing protection for the circuit.

Good heat resistance, low temperature coefficient, and low noise.

High load power, flame retardant.

Operating environment temperature: -55 ℃~+125 ℃