WEE Technology Company Limited - WEE are Capacitors Specialist

What is The function of the resistor?

The obstruction effect of an object on the passage of current is called resistance, and the components made by utilizing this obstruction effect are called resistors, abbreviated as resistors.

Resistors are the most widely used type of circuit components, accounting for over 30% of the total number of components in electronic devices. Their quality has a great impact on the stability of circuit operation.

In a circuit, the main function of a resistor is to stabilize and regulate the circuit

Current and voltage, which play a role in voltage reduction, voltage sharing, current limiting, shunt, isolation, filtering (in conjunction with capacitors), matching, and signal amplitude regulation.

The symbol of resistors in circuits: Resistors are the most basic and common electronic components in electronic circuits, and resistors are generally represented by written symbols such as "R", "RN", "RF", "FS", etc.

WEET SQZ 5W Standing Type Through Hole Terminal Cement Ceramic Resistor PCB Mounting Cross to YAGEO

| Power Rating 70℃ | 2W | 3W | 5W | 7W | 10W |

| 3WS | 5WS | 7WS | 10WS | - | |

| Series Number | SQM | ||||

| Operating Temp. Range | -55℃~ +155℃ | ||||

| Max. Working Voltage | 250V | 350V | 350V | 500V | 500V |

| Max. Overload Voltage | 500V | 700V | 700V | 1000V | 1000V |

| Dielectric Withstanding Voltage(AC) | 500V | 700V | 700V | 1000V | 1000V |

| Value Range ±5% (Ceramic Core) | 0.1Ω - 47Ω | 0.1Ω - 100Ω | 0.1Ω - 180Ω | 0.1Ω - 470Ω | 0.1Ω -680Ω |

| Value Range ±5% (Metal Oxide Film) | 48Ω -100KΩ | 110Ω -100KΩ | 180Ω -100KΩ | 471Ω -10KΩ | 681Ω -10KΩ |

| Temp. Coefficient (PPM) | ±300ppm/℃ | ||||

WEE Technology Company Limited - WEE are Capacitors Specialist

WEET Suggestion for using resistors:

It is recommended to leave a power margin of 1.5 times when using resistors in the circuit. For example, if the voltage in the circuit is 100V, the current is 0.01A, and the calculated power is P=100 * 0.01=1W, then the resistor cannot be used as 1W. If there is no 1.5W resistor, a 2W resistor needs to be used.

Advantages of cement resistance:

1. Features such as shock resistance, moisture resistance, heat resistance, good heat dissipation, and low price.

2. Fully insulated, suitable for printed circuit boards.

3. Wire winding on the porcelain rod and then welding the joints to produce accurate resistance values and extend service life.

4. High resistance values are made using metal oxide film (MO) instead of wire winding.

5. Excellent heat resistance, low resistance temperature coefficient, and linear variation.

6. Short term overload resistance, low noise, resistance value unchanged over the years.

7. Good explosion-proof performance, providing protection.

WEE Technology Company Limited - WEE are Capacitors Specialist

3.3Ω 20W ±5% Size L*H*W±1.5mm:63*12.5*12.5 ±300ppm/℃

3.9Ω 20W ±5% Size L*H*W±1.5mm:63*12.5*12.5 ±300ppm/℃

8.2Ω 20W ±5% Size L*H*W±1.5mm:63*12.5*12.5 ±300ppm/℃

6.8Ω 20W ±5% Size L*H*W±1.5mm:63*12.5*12.5 ±300ppm/℃

18Ω 20W ±5% Size L*H*W±1.5mm:63*12.5*12.5 ±300ppm/℃

WEE Technology Company Limited - WEE are Capacitors Specialist

WEET WAA Axial 85C 2000H Polarized Aluminum Electrolytic Capacitors Standard Low Voltage

WEET WAB Axial 105C 1000H Polarized Aluminum Electrolytic Capacitors Super Low Voltage

WEET WMN BP Axial Bi polar 120HZ Aluminum Electrolytic Capacitors For Audio and Speaker System: Low Dissipation Factor, MAX 5% at 120Hz, Bi-Polarized,105℃ 1000 hours

WEET WMM BP Axial Bi polar Aluminum Electrolytic Capacitors for Audio and Speaker System: Low Dissipation Factor MAX 5% at 1KHz,Bi-Polarized,105℃ 1000 hours

WEET WMS NP Axial Non polar Aluminum Electrolytic Capacitors for Audio and Amplifier System: Low Dissipation Factor MAX 10 % at 1KHz,Bi-Polarized,105℃ 1000 hours

https://www.weetcap.com/Aluminum-Electrolytic-Capacitors/

WEE Technology Company Limited - WEE are Capacitors Specialist

WEE Technology (WEET) Company Limited is specialized in manufacturing full range of capacitors for more than 20 years history. WEET products can be packaged in various packing based on customer request. Cut leads, long leads, Straight leads, Kinked leads are available. For Axial and Radial capacitors, our standard packing is bulk and ammo in box, tape and real. For SMD capacitors, tape and real, ammo and real packing. You can refer to WEET sales engineers for the best packing solution for all of your products.

https://www.weetcap.com/Products-Packing/

WEE Technology Company Limited - WEE are Capacitors Specialist

Welcome all of you view the latest company videos on WEET official website.

https://www.weetcap.com/Company_Videos/

WEE Technology Company Limited - WEE are Capacitors Specialist

We would like to say thank you in year 2022. Let us welcome the new year of 2023

All the best to you. Check more about WEET company information at below links.

https://www.weetcap.com/Products/

https://www.weetcap.com/Company_Photos/

https://www.weetcap.com/Company_Quality/

https://www.weetcap.com/Products-Packing/

WEE Technology Company Limited - WEE are Capacitors Specialist

What are the differences between carbon film resistance and metal film resistance

1. The carbon film resistance has a negative temperature coefficient, while the metal film resistance has a small positive temperature coefficient;

2. Carbon film resistance is an ordinary resistance, and its accuracy is generally not very high, while metal film resistance has higher accuracy than carbon film resistance. However, due to the improvement of current technology, this method is sometimes not very desirable;

3. The appearance of carbon film resistors is mostly khaki or pink, while the appearance of metal film resistors is mostly blue;

4. By looking at the color of the protective paint, the black protective film is carbon film resistance, while the bright white protective film is metal film resistance.

What are the characteristics of carbon film resistance and metal film resistance

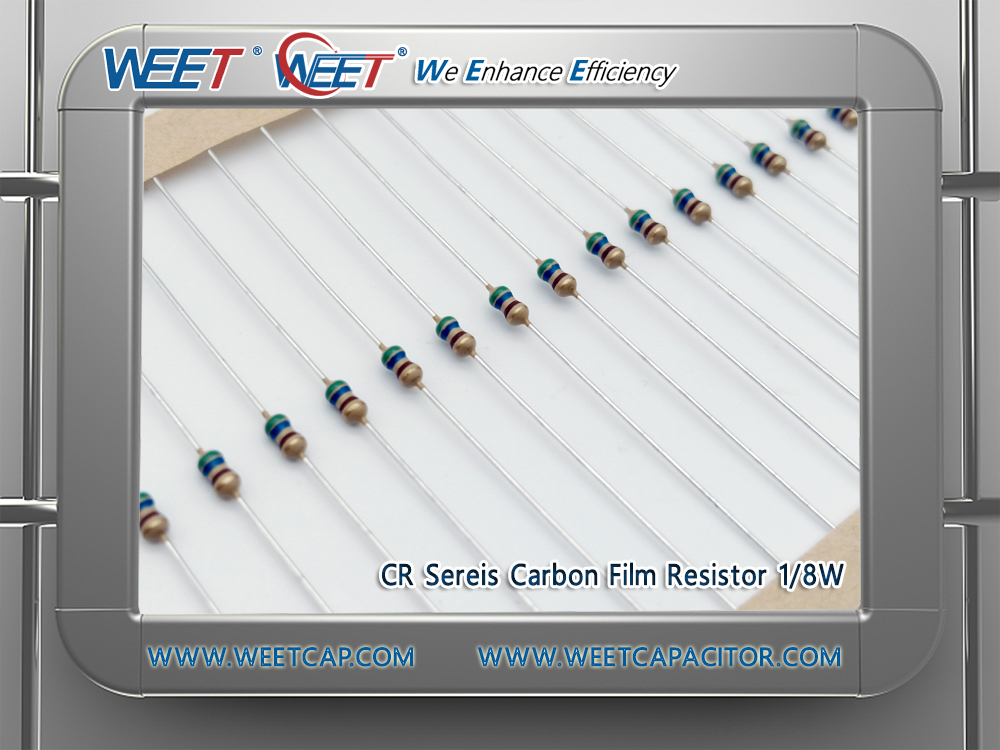

1、 Carbon film resistance

For the carbon film resistance, it uses carbon to precipitate on the magnetic rod or porcelain tube, and at the same time forms a layer of crystalline carbon film on its surface. By changing the thickness of the carbon film and changing the degree of the carbon film resistance by grooving, the required resistance value is finally obtained. Finally, the surface is coated with epoxy resin to strengthen the sealing. The appearance color is basically earthy yellow, but there are also other colors, such as pink.

The color ring is composed of four rings. The resistance range is 1 Ω~10M Ω. The rated power is 0.125W, 0.25W, 0.5W, 1W, etc. The accuracy range is ± 10%, ± 5%, ± 2%. This resistance is generally large and is often used in low-cost products, such as power supply products and chargers. This type of resistance is not recommended for starting resistance, because the impact resistance is relatively defective.

2、 Metal film resistance

As for the metal film resistor, it is formed by vacuum evaporation or infiltration on the ceramic pipe rack to form a layer of metal film, which is attached to the surface of white ceramics. It is cut to adjust the resistance value to obtain a more precise resistor. This resistor has high precision, small volume, good stability and high cost. It is usually used in wireless electronic equipment, especially in occasions with higher precision requirements. Its appearance color is mostly blue.

WEE Technology Company Limited - WEE are Capacitors Specialist

Industry's lower cost and deliver from stock.

Exceptional long term stability.

Exceeds carton comp MIL-R-11 performance

Standard tolerance: ±2%, ±5%

Variety of packing: Bulk , strip pack. 26mm and 52mm tape and reel, cut and formed

https://www.weetcap.com/Resistors/WEET-CR-Sereis-Carbon-Film-Resistor.html

Featuring consistency and stably-controlled, these carbon film resistors with reasonable prices are widely and largely be used in the electronic, electrical and information industries.

This resistor is a ceramic bar tightly coated with a carbon film which is composed of carbon separately from organic compound through the treatment of high temperature vacuum.

After the carbon coated bar is connected with proper joint and engraved with grooves, its surface is finished with epoxy resin so that the bar is enclosed with a protective film.

Application: all kinds of customer devices.