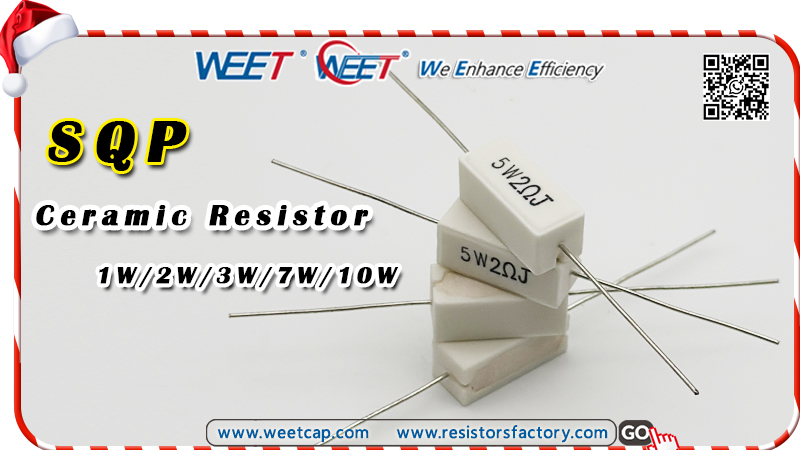

Ceramic composition resistor widely used in industrial control, power supply equipment, automotive electronics, instrumentation and other scenarios, how much do you actually know about SQP Ceramic Resistor 5 watts?

Flameproof ceramic resistor is manufactured by winding metal alloy resistance wire around a ceramic rod, which is then placed in a refractory ceramic case and encapsulated with non-flammable cement.

Advantages of ceramic composition resistor:

Excellent heat resistance

Ability to withstand short-term overloads

Low noise

Superior explosion-proof performance

Reliable protection capability

Working principle of ceramic resistors:

The core operation of ceramic resistors 1W/2W/3W/7W/10W is based on the Joule heating effect of electric current and the resistive properties of ceramic materials. Through the synergistic effect of the ceramic substrate and conductive medium, they achieve current limiting, energy dissipation, and signal regulation.

Refer to the ceramic resistor shown in the figure below.

SQP 5Watts ceramic resistor Ohm Range:

Wire Wound: 0.1Ω- 47Ω

Metal Oxide: 50Ω-100KΩ

Contact Us: Sales@weetcap.com

WEE Technology Published on Nov 27, 2025

Film Rod High Power Resistors are widely used in large quantities, and their price has attracted much attention. Do you know what is the price of WEET MOF 2W resistive ceramic rods?

INTRODUCTION

In fact, the price cannot be directly defined as it is affected by numerous factors.

The price of resistive ceramic rods is closely related to multiple aspects such as raw material quality, product specifications, and production processes. Meanwhile, changes in procurement models and market environments can also cause fluctuations in their prices.

Product Specifications and Parameters: This is a key factor affecting the price, mainly including two aspects: power and resistance value.

Raw Material Quality: The quality and price of its core constituent materials directly determine the cost. Additionally, if the metal resistance wire in the rod has high purity and good high-temperature resistance, the material cost will increase, ultimately leading to a higher product price.

Production Process Level: Ordinary resistive ceramic rods are produced using mature standard processes, featuring high efficiency, low cost, and affordable prices. In contrast, high-temperature resistive ceramic rods require special processes to enhance their high-temperature resistance and stability.

Market Supply and Demand & Industry Environment: When industries such as electric vehicles and smart homes develop rapidly, the market demand for resistive ceramic rods surges. If the supply fails to keep up with the demand, the price will rise.

Procurement Quantity: For bulk purchases, suppliers will offer price discounts. Generally, the larger the procurement quantity, the lower the unit price.

SUMMARY

The above are the factors influencing the price of resistive ceramic rods. For inquiries about the price, welcome to contact WEET, and we will tailor the most favorable ordering plan for you.

Contact us:Sales@weetcap.com

WEE Technology Published on Nov 26, 2025

Those colorful resistors we see in daily life - you'd never guess they're the original form of resistive ceramic rods before being painted! So, what is MF resistive ceramic rod? What is its function?

A Rod Resistors With High Stability is an electronic component based on ceramic materials such as alumina and zirconia. Resistive ceramic rod is mainly used in circuits requiring high insulation and high temperature resistance, and is commonly found in industrial equipment, electronic devices, and other fields.

Resistive ceramic rod is classified into three types based on different materials:

Thick-film resistive ceramic rod: Manufactured using isostatic pressing technology, it is suitable for precision resistor applications.

Zirconia ceramic rod: Boasting superior high-temperature resistance, it is often used as an insulating structural part in high-temperature environments.

Alumina ceramic rod: Contains 95%~99% alumina, featuring excellent insulation performance. It is suitable for high-frequency circuits, inductor cores, etc.

What is Film Rod High Power Resistors function?

Industrial machinery: High-temperature components such as electric furnace tubes and silicon carbide rod protection tubes.

Electronic devices: For example, high-frequency inductor coils and insulating skeletons used in vacuum equipment.

Contact us:Sales@weetcap.com

WEE Technology Published on Nov 25, 2025

Carbon film resistors 1/4W and wire wound resistors are two widely used electronic components. So, where to use carbon film and wire wound resistors?

Carbon Film Resistor vs Wire Wound Resistor

KNP High Stability Carbon Film Resistor:

Featuring a wide resistance range, low cost, and compact size, they are suitable for low-to-medium power applications:

1. Consumer Electronics

TVs, radios, and laptops (used in audio circuits);

Microwaves, refrigerators, and air conditioners (applied in control panels and sensor circuits).

2. Automotive Electronics

Non-core control circuits, such as instrument panels and door lock systems.

3. Industrial Control

General PLC interface circuits.

CF Wire Wound Resistor:

Wire wound resistors 1W / 2W / 5W / 10W are wound with metal alloy wire, they offer advantages of high-power handling, high precision, and low temperature coefficient:

1. Industrial Electrical Equipment

Electric welders, frequency converters, and braking circuits, etc.

2. Automotive Electronics

Automotive air conditioning compressor drives, engine control units (ECUs), etc.

3. Aerospace

Satellites, spacecraft, and military communication equipment.

4. Medical Equipment

Magnetic Resonance Imaging (MRI) machines, ultrasonic diagnostic equipment, etc.

Contact us:Sales@weetcap.com

WEE Technology Published on Nov 24, 2025

Have you ever seen a radial power resistors SQP?

High power ceramic resistors are widely used due to their core advantages such as high temperature resistance, strong stability, and moisture resistance, especially in the industrial, power, and electronic equipment fields. So, what are radial power resistors made of to achieve such outstanding performance?

Radial power resistors are manufactured by winding a metal alloy resistance wire around a ceramic rod, placing the assembly into a fire-resistant ceramic casing, and then encapsulating it with non-flammable, heat-resistant cement.

The rated powers of the resistors are as follows: 2W, 3W, 5W, 7W, 10W, 3WS, 5WS, 7WS, 10WS.

Taking the high-power ceramic resistor in the figure as a reference:

Series Number: SQM

It is 5W, 3Kohm.

Value Range ±5% (Ceramic Core): 0.1Ω - 180Ω

Value Range ±5% (Metal Oxide Film): 180Ω -100KΩ

Operating Temp. Range: -55℃ ~ +155℃

Temp. Coefficient (PPM): ±300ppm/℃

Free samples are available upon request if needed.

Contact us:Sales@weetcap.com

WEE Technology Published on Nov 21, 2025

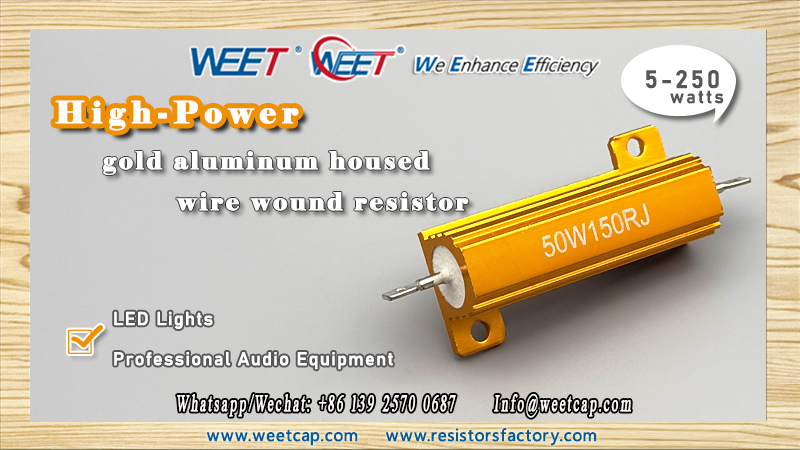

In devices such as frequency converters, automotive LED lights, and professional audio equipment, there lies a key "guardian" - the high power AH gold aluminum housed wire wound resistor.

So, what is wire wound resistor made of?

It features a stable framework of high-temperature resistant ceramic rod, wrapped with high-quality alloy wire as the resistance core. It is then precision-potted with high-insulation paste and paired with an aluminum alloy housing that combines heat dissipation and protection, ensuring stable performance and enhanced operational safety.

But what characteristics make it stand out?

High rated power and ultra-precision (accuracy up to ±1%).

Excellent stability with weather resistance and reliable performance. The aluminum alloy housing not only dissipates heat quickly but also isolates external dust and moisture.

Wide power range, offering 6 models (5 to 250 watts) to adapt to different power scenarios.

Resistance Tolerance: ±10%, ±5%, ±3%, ±2%, ±1%, ±0.5%.

Superior heat dissipation, operating temperature range from -55℃ to +275℃.

Taking the 50W wire wound resistor for TUBE AMP AUDIO in the following figure as a reference, its resistance range is 0.1ohm ~ 100Kohm.

Please feel free to contact WEET if you have any needs. We will be dedicated to serving you!

Contact us:Sales@weetcap.com

WEE Technology Published on Nov 20, 2025

What is the KNP audio amplifier resistor?

KNP resistor for audio amplifier also known as wire wound audio resistor. As the name suggests, an audio amplifier resistor is a resistor used for audio applications.

What role do wire wound resistor play?

KNP Wire wound resistor play roles such as noise suppression and circuit protection in audio circuits.

What is wire wound resistor made of?

It is made by winding resistance wire.

What about the resistor packages?

Bulk tape packaging and strip packaging.

Resistors are widely used, but different applications require different types of resistors. Do you know the differences between radial and axial resistors?

Let WEET tell you, the core difference between radial and axial resistors lies in their lead arrangement and application scenarios.

INTRODUCTION

Resistors Types

Through hole resistor: Leads extend from both ends of the resistor body along the central axis.

Radial resistor: Leads protrude from the same end (or adjacent positions) of the body.

Mounting Method and Space Occupation

Through hole resistor: Axial resistor sizes for through-hole mounting, requiring linear space reserved along the direction of the leads.

Radial resistors: Support through-hole mounting and surface mount technology (SMD). Vertical mounting saves horizontal space, enabling a more compact layout.

Application Scenarios

Through hole resistor: Commonly used in traditional circuits, audio equipment, and projects with fixed requirements for lead spacing.

Radial resistors: Preferred for miniaturized devices such as printed circuit boards (PCBs) and high-density circuits.

https://www.resistorsfactory.com/Axial-Resistors/

Contact us: Sales@weetcap.com

WEE Technology Published on Nov 18, 2025

As one of the most basic components in electronic circuits, a resistor exerts a certain hindrance to the flow of electric current. But do you know how to read carbon film resistor color code?

These colorful bands actually indicate the resistor's resistance value - a detail that can be confusing for many beginners. However, with WEET guidance, you'll surely learn to identify the resistance value quickly.

First, carbon film resistor is generally classified into 4-band resistors and 5-band resistors based on the number of color bands.

Start by memorizing this mnemonic:

Brown=1, Red=2, Orange=3, Yellow=4, Green=5, Blue=6, Violet=7, Gray=8, White=9, Black=0.

Resistance value:

Gold=±5%, Silver=±10%.

Take the CF Series 4-band resistors in the figure below as an example:

1st digit: Yellow=4

2nd digit: Red=2

Multiplier: 2×100

Tolerance: ±5%

So, the resistance value of this resistor is 4K2 Ω.

After this explanation, you must have a general understanding. Feel free to contact WEET if you need carbon film resistor!

More information:WEET CF Series Carbon Film Resistor-Axial Resistors-WEET Resistors | China MF CF MOX KNP Resistors Factory-

Contact us:Sales@weetcap.com

WEE Technology Published on Nov 14, 2025

Through hole resistors are hidden in various electrical devices and play a huge role, so have you ever wondered about their size?

Next, I will elaborate on several features related to through hole resistors MO.

Features:

Operating Temp. Range: -55℃~ +155℃

Wide Resistance range: 1Ω~180KΩ

Standard tolerance: ±1%, ±2%, ±5%

Temp. Coefficient (by Type): ±350ppm/℃

Dimension(mm):

Series: MO 2W 47R

L: 15±0.5mm

ØD: 5.0±0.5mm

H: 32±2mm

Ød: 0.78±0.05mm

Click the link for more information about through hole resistors:

WEET-MO-Sereis-Metal-Oxide-Resistor

Contact us:Sales@weetcap.com

WEE Technology Published on Nov 13, 2025