Dear Customers,

The International Workers' Day, also known as Labor Day or May Day. The ultimate goal of International Workers' Day is to promote equity, justice and dignity for all working people across the world.

WEE Technology would like to thanks for all the WEET worker devotion and dedicated work spirit. We wish everyone will enjoy a happy and relaxed May day.

Please send your inquiry as usual, WEET sales team will reply you at the first time when we resume work, thank you.

2025 International Labor Day Holiday Notice

Holiday From 1st May to 5th May

Resume Work On 6th May 2025

WEE Technology Company Limited

Dear Customers,

We would like to inform you that we will have Tomb Sweeping Day this week. Please kindly be noted of our holiday notice as below, thank you.

Qingming Festival/Ching Ming Festival, also called Tomb-Sweeping Day in English, is a traditional festival in China. The main tradition for the festival is to honor the ancestors and deceased loved ones.

2025 Tomb Sweeping Day Holiday Notice

Holiday From 4th April to 6th April

Resume Work On 7th April 2025

WEE Technology Company Limited

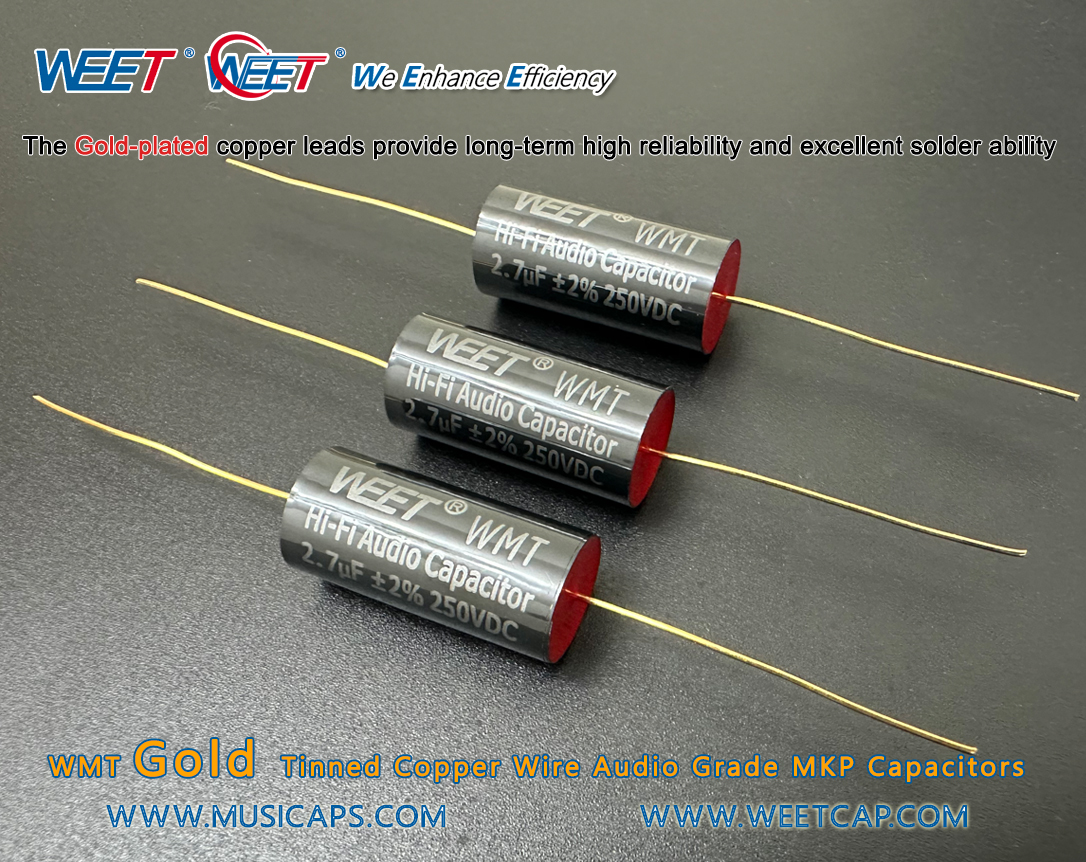

In order to provide the best sounding performance, WEET upgrade lead from tinned copper wire to gold/silver copper wire.

This improvement are highly welcomed for high end audio application manufacturer, thank you.

https://www.musicaps.com/product/WEET-WMT-Silver-Gold-Tinned-Copper-Wire-Condenser-Audio-Grade-MKP-Capacitors.html

Quick transient design

High Precise Capacitance ±2%, ±3%, ±5%

Very Low Dielectric absorption factor Very Low Dissipation factor, Very Low ESR,

Very Low Inductance Excellent handling of high current audio pulses

The gold-plated copper leads provide long-term high reliability and excellent solder ability

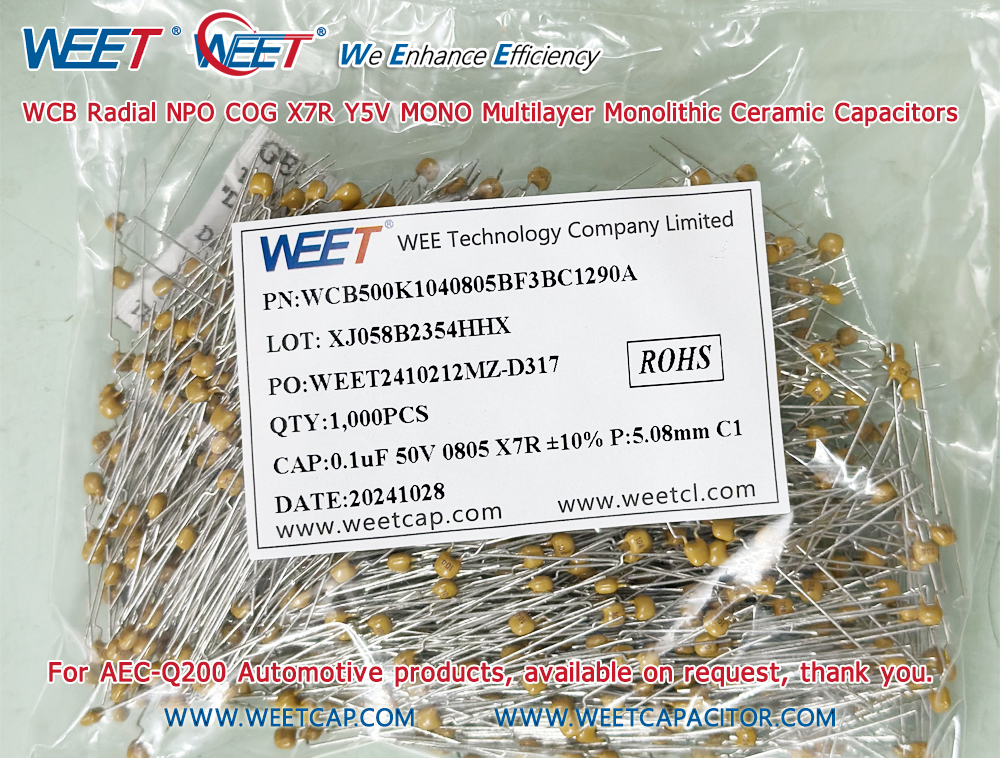

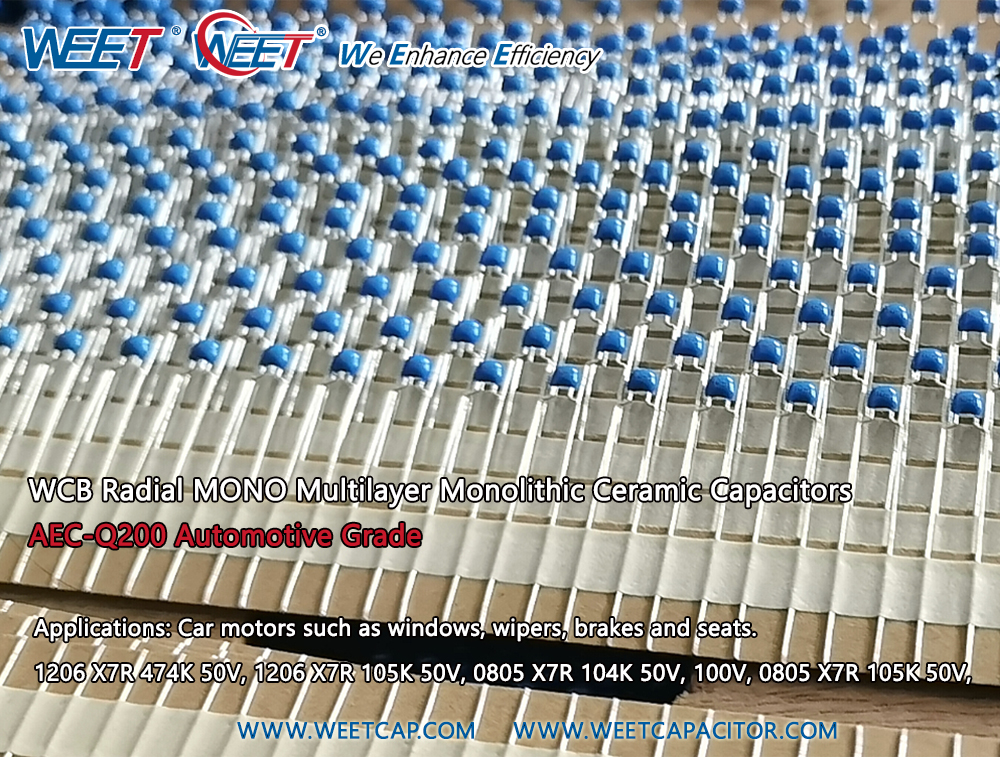

In the field of automotive electronics, AEC-Q200 is an important standard for automotive grade capacitors. It is a high-performance capacitor that can meet the needs of automotive electronic systems for high reliability, high stability, and long lifespan.

AEC-Q200 capacitor is a multi-layer ceramic capacitor with the following main characteristics:

1. High reliability: AEC-Q200 capacitors are made of multi-layer ceramic materials, which have good thermal stability and electrical performance. They can work stably in harsh environments such as high temperature, low temperature, high temperature and high humidity, ensuring the reliability of automotive electronic systems.

2. High stability: AEC-Q200 capacitors have a low temperature coefficient and stable capacity and voltage characteristics, which can effectively suppress noise and interference, ensuring the stability of automotive electronic systems.

3. Long life: AEC-Q200 capacitors adopt a long life design, which can meet the lifespan requirements of automobiles for more than 10 years, effectively reducing the frequency and cost of capacitor replacement.

4. Miniaturization: AEC-Q200 capacitors are made of high-density multi-layer ceramic materials, which can achieve miniaturization design and facilitate installation in automotive circuits.

5. Good self-healing performance: AEC-Q200 capacitors have self-healing performance. When a short circuit or open circuit fault occurs in the capacitor, it can automatically repair the fault and ensure that the capacitor continues to work normally.

WCB Radial MONO Multilayer Monolithic Ceramic Capacitors AEC-Q200 Automotive Grade, 1206 X7R 474K 50V, 1206 X7R 105K 50V, 0805 X7R 104K 50V, 100V, 0805 X7R 105K 50V,

Applications: motors such as windows, wipers, brakes and seats.

The application of AEC-Q200 capacitors is widely used in automotive electronic systems, including the following aspects:

1. Automotive engine control system: The HeYue AEC-Q200 capacitor plays an important role in the automotive engine control system, enabling functions such as signal processing, sensor detection, and actuator control. These capacitors need to have high reliability, long lifespan, and high stability to ensure the normal operation of the engine control system.

2. Automotive body control system: Heyue AEC-Q200 capacitors are widely used in automotive body control systems for functions such as lighting control, window lifting control, and air conditioning control. These capacitors need to have characteristics such as miniaturization, high reliability, and long lifespan to ensure the stability and reliability of the vehicle control system.

3. Automotive safety control system: The AEC-Q200 capacitor from Heyue plays an important role in automotive safety control systems, such as ABS anti lock braking system, ESP electronic stability system, etc. These capacitors need to have high reliability and long lifespan to ensure the stability and reliability of the safety control system.

4. Automotive entertainment and information systems: Heyue AEC-Q200 capacitors are widely used in functions such as audio systems, navigation systems, and in car communication in automotive entertainment and information systems. These capacitors need to have high reliability and long lifespan to ensure the normal operation of entertainment and information systems.

In summary, the AEC-Q200 capacitor, as a high-performance capacitor, plays an important role in automotive electronic systems. Its high reliability, stability, long lifespan, and miniaturization can meet the needs of automotive electronic systems and improve the performance and safety of automobiles.

Ultra high voltage axial thin film capacitor, this 0.00025uF 12.5KV through-hole capacitor stands out in high voltage applications with its outstanding performance.

High voltage endurance: This capacitor can withstand DC voltages up to 12500V DC, making it an ideal choice for fields such as high-voltage power supplies, power electronics equipment, and medical devices.

Low loss: The low loss and internal resistance of metalized thin film axial capacitors ensure their stable operation at high efficiency, even under high voltage.

Long lifespan: Due to its superior design and materials, this capacitor has a long service life and can maintain stable performance under long-term high-voltage working conditions.

Stability performance: The temperature and frequency stability of metalized thin film axial capacitors make them excellent and reliable in high-voltage and high-frequency applications.

Overall, the advantages of ultra-high voltage metalized thin film axial capacitors include high voltage endurance, low loss, long lifespan, and stability performance, making them an ideal choice for handling high voltage applications.

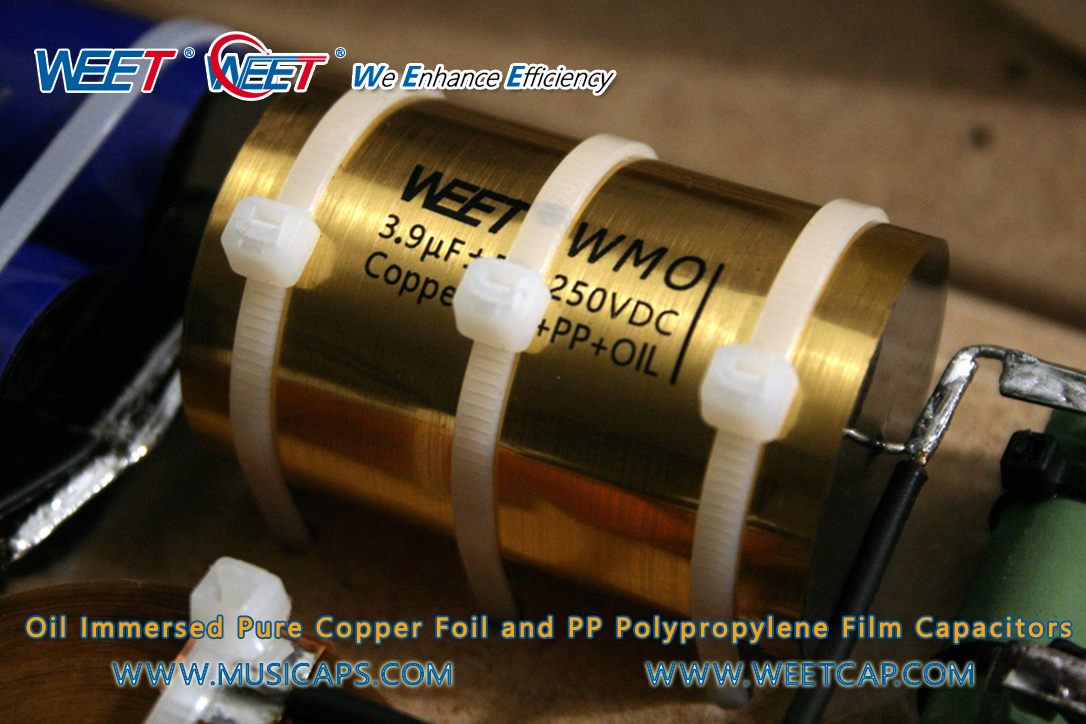

WEET Capacitors Best Audio Capacitors for OEM Speaker Amplifier Mnufacturer and Crossover Assembly etc.

Check More Audiophiler Capacitors Review By Below Link:

https://www.musicaps.com/WEET-Full-Range-of-Audio-Capacitors-Customer-Testimonials.html

https://www.musicaps.com/Copper-Foil-and-Film-Capacitors-Test-Reviews.html

The WMO caps have fast, uncolored sound, full of life, dense body, wide soundstage, natural organic voices etc. I rank these caps at 10/10 , equal with the best caps available.I want to thank you for the opportunity to try them.

--- From LampizatOr, Łukasz Fikus, Poland

I didn't write about my impressions of WMO right away, I decided to wait for the customer's opinion. He says that TW29BN-B now plays what it hadn't played with Jxxxxxx Alumen Z-Cap before, the elaboration has become noticeably deeper, there are moments in familiar recordings that I hadn't heard before. WMO reveals the speaker's capabilities much better. My impressions coincide with the customer's impressions.

--- From Alexander, Russia

This probably is the best compliment I can make for a capacitor, doing it's job and leaving no trace of being there at all. For me this is the endstation in relation to upgrading my crossovers, it seems it sounds too good to be true, but I really don't feel the need of changing anything, anymore.

--- From Alex Bartels, The Netherlands

For capacitive divider power supply circuit only contains a few simple components, so its structure is simple and reliable. In this circuit, the most important electronic component is the resistive capacitive buck capacitor. Should the capacitive divider power supply capacitor be an X2 capacitor or a CBB capacitor?

The answer is: X2 capacitors and many CBB capacitors can be used as resistance capacitance step-down capacitors.

X2 safety capacitor specifically designed for capacitive divider power supply

X2 capacitors are mainly used to suppress electromagnetic interference from power sources. Ordinary X2 capacitors cannot be used as resistance capacitance step-down capacitors, otherwise there will be problems such as rapid capacity decay and extremely short service life.

1, If you want to use it in capacitive divider power supply circuits, you must use WFC-A series capacitors specifically designed for resistive capacitive divider.

The X2 safety standard capacitor for resistive capacitive voltage reduction is a type of capacitor used in resistive capacitive voltage reduction circuits, which has excellent electrical and stability performance. This type of capacitor usually uses high-quality dielectric materials and electrode materials, which have the characteristics of high withstand voltage, low loss, good stability, long service life, and comply with safety standards, with safety and reliability.

2. CBB22 capacitor specifically designed for resistive capacitive voltage reduction.

In order to avoid oxidation of the metal coating caused by high voltage communication, the CBB22 capacitor specifically designed for resistive capacitive voltage reduction uses different metal thin films, which can significantly slow down the decay rate of the capacitance value. At the same time, the production process is more complex and must be carried out in a constant temperature and humidity workshop to reduce the water content of the production environment and minimize the adsorption of moisture by the product. The zinc aluminum film capacitor core is immediately sealed after heating up, and the product temperature is increased while being evacuated and cured.

3. MPB box capacitors specifically designed for capacitive divider power supply

This type of capacitor is similar to the CBB22 capacitor, with the same internal capacitor core, except that the MPB capacitor has better performance and longer lifespan.

X2 safety capacitors are mainly divided into two types: one is anti power electromagnetic interference, and the other is resistance capacitance voltage reduction. Today, we will focus on introducing the X2 safety capacitors specifically designed for resistance capacitance voltage reduction.

The X2 safety capacitors used for voltage reduction and the capacitors used for anti-interference, although both are made by winding metalized polypropylene film, still have certain differences in their internal composition,

The main adjustment is to adjust the zinc aluminum ratio of the metal film, and at the same time, the resistance capacitance voltage reduction X2 safety capacitor adopts a double 85 characteristic metalized polypropylene film and epoxy resin cured sealing adhesive.

This is used in resistive capacitive buck circuits, which means that the capacity decay is smaller and the lifespan of the capacitor is longer

Can ordinary anti-interference X2 capacitors be used in resistive capacitive buck circuits? Indeed, there have been some customers who are not familiar with X2 capacitors and directly use ordinary X2 capacitors for anti-interference in resistive capacitive voltage reduction circuits. The result is that their capacity decays quickly. After a few months of use, due to the severe capacity decay of X2 capacitors, the power supply to the resistive capacitive voltage reduction circuit is insufficient, and the electrical appliances cannot be used normally.

What are the characteristics and functions of the X2 capacitor for resistive capacitive voltage reduction? We call the optimized series X2 certified AC safety capacitors for resistance capacitance voltage reduction. They use polymer polypropylene film dielectric, thickened metalized electrodes, fully automatic spray welding process, 94V0 flame-retardant PBT plastic shell, moisture resistant epoxy resin sealing, and CP wire lead out. High voltage resistance, moisture and heat resistance, low capacitance drop, specifically designed for resistive capacitive voltage reduction circuits, such as LED driver modules, electric meters, small household appliances and other low-power electronic consumer products.

Reminder: When choosing X2 capacitors in the future, it is important to clarify whether they are used for anti-interference or resistive capacitive voltage reduction applications. If using resistive capacitive voltage reduction circuits, X2 safety capacitors specifically designed for resistive capacitive voltage reduction must be used, otherwise the circuit is prone to problems.

X2 safety capacitors are commonly used in power circuits to suppress electromagnetic interference. They are installed between the live and neutral wires of the power supply to filter out high-frequency noise, ensure the stability of the power supply, and reduce the potential impact of electromagnetic interference on other electronic devices.

In fact, X2 safety capacitors can be further divided into many types. Taking the WFC-A series X2 safety capacitors from WEET as an example, they can be divided into suppression of power electromagnetic interference type, PD fast charging dedicated type, resistance capacitance voltage reduction dedicated type, double 85 type, moisture-proof type, etc.

In what occasions are moisture-proof X2 safety capacitors used?

This X2 capacitor is suitable for capacitor voltage reduction circuits connected in series with power sources, such as smart meters, LED power supply modules, and other harsh application environments.

What are the characteristics of moisture-proof X2 safety capacitors?

1. The capacity attenuation is extremely small.

Compared with the anti-interference X2 capacitor, our moisture-proof X2 capacitor has less capacity attenuation and can be used in harsh environments such as high temperature and high humidity for a long time with excellent capacity stability.

The moisture-proof X2 capacitor was designed with long-term stability in mind, with minimal capacity decay and the ability to provide stable performance throughout the entire lifespan of the device.

2. Capacitors have self-healing properties and can withstand surge voltage impacts.

3. Excellent flame retardancy and better high-temperature resistance.

4. Better high temperature resistance. The moisture-proof X2 safety capacitor can operate stably in high temperature environments, and its design considers performance maintenance at high temperatures to ensure that there will be no performance degradation or capacity degradation under long-term high temperature loads.

5. Better moisture resistance.

Due to the fact that some electronic devices may be used in humid environments, these capacitors typically have good moisture resistance and can maintain stable electrical characteristics in high humidity environments.