WEE Technology Company Limited - Manufacturer For Full Range of Resistors

Detailed explanation of the three pin connection method for multi turn precision adjustable potentiometers

1、 Introduction to Multiturn Precision Adjustable Potentiometers

Multi turn precision adjustable potentiometer is a commonly used electronic component used to adjust linear voltage and current in circuits. It has high accuracy, reliability, and is suitable for various circuits, and is widely used in the electronics industry.

2、 The connection method of the three legs of a multiturn precision adjustable potentiometer

The three legs of a multi turn precision adjustable potentiometer are the middle leg, sliding leg, and fixed leg. According to different needs, the middle foot and sliding foot can be connected to the circuit separately, and the fixed foot is usually used for power or ground.

A. Single circle connection method

The single loop connection method is to connect the sliding foot and the middle foot together, and fix the foot to ground or power. This connection method is suitable for single voltage circuits, such as audio amplifiers, power amplifiers, etc.

B. Double circle connection method

The double loop connection method is to divide an adjustable potentiometer into two parts, connect the two fixed pins together, and at the same time connect the middle pin and the two sliding pins to two separate circuits. This connection method is suitable for circuits that require two different voltages or currents, such as power amplifier front-end circuits.

C. Three circle connection method

The three circle connection method is to divide an adjustable potentiometer into three parts, connect two sliding pins and one fixed pin into one circuit, and at the same time connect the middle pin and the other fixed pin to another circuit. This connection method is suitable for situations that require two different voltages or currents, such as audio frequency EQ circuits.

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

Precautions for using WEET potentiometers:

(1) In order to prevent the pin contacts and conductive layer of the WEET potentiometer from deteriorating or burning out, the working current of the potentiometer should not exceed the rated current.

To avoid potential damage to the potentiometer.

(2) If the WEET potentiometer is used for a long time, there may be some loud noise or inflexible shaft adjustment.

In this case, there may be a lack of specialized lubricating oil inside the potentiometer.

By adding appropriate lubricating oil, the two types of faults can be solved.

(3) Do not tap or shake the WEET potentiometer during installation. Because the interior of the potentiometer is composed of various components,

it is possible that these components may fall off due to violent shaking or vibration. So, more precautions are needed for this.

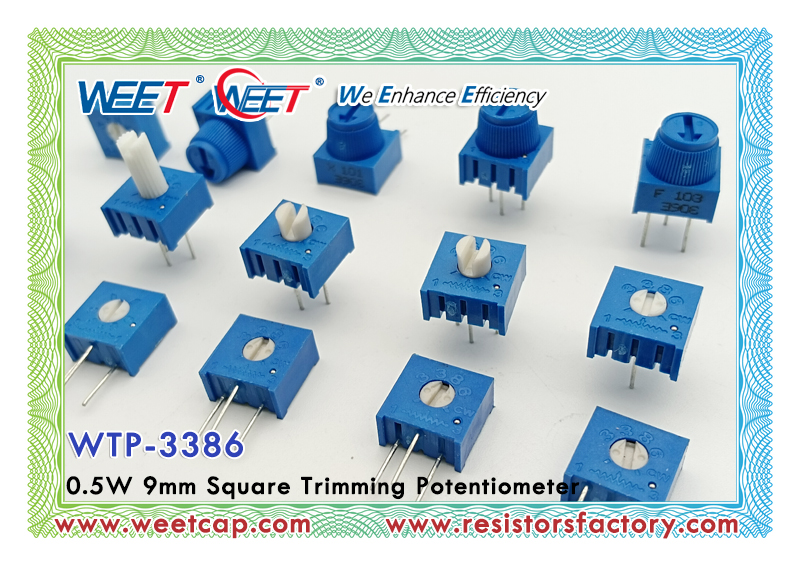

https://www.resistorsfactory.com/Datasheet/WEET-WTP-3386-0.5W-9mm-Square-Trimming-Potentiometer.pdf

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

Suggestion for storing WEET potentiometers:

(1) Avoid storing WEET potentiometers and items with chemical components to prevent them from corroding the internal components of the potentiometer.

So it should be isolated and stored from items containing these chemical components.

(2) WEET potentiometers should be stored in high temperature environments, as storing them in high temperature areas may cause accidents such as spontaneous combustion of internal components.

So it should be stored and not placed in a high temperature place.

(3) WEET potentiometers should not be stored in damp places, as storing them in damp places can easily cause the internal components of the potentiometer to become damp and fail.

So the WEET potentiometer should be stored in a ventilated place.

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

Trouble shooting of Timming potentiometer soldering

The soldering of potentiometers is one of the reasons that can easily cause malfunctions, and most customers still use manual soldering.

In addition, some large enterprises use high-frequency soldering methods.

There are some things to pay attention to. When using manual soldering method, the potentiometer should be completed as quickly as possible during the soldering operation, preferably within 3 seconds.

The highest temperature of the soldering iron contact should be below 270 degrees.

If the time is too long or the temperature is too high, it can cause various reasons such as poor contact of the potentiometer.

When welding, be cautious when using flux and avoid using water-soluble flux, otherwise it will promote metal oxidation and material mold.

When using high-frequency soldering, pay attention to the plastic parts inside the potentiometer, such as the dial knob, plastic push handle, plastic handle, etc.,

so that the melting point can reach the required temperature for high-frequency soldering. If not, please replace the high-temperature resistant parts.

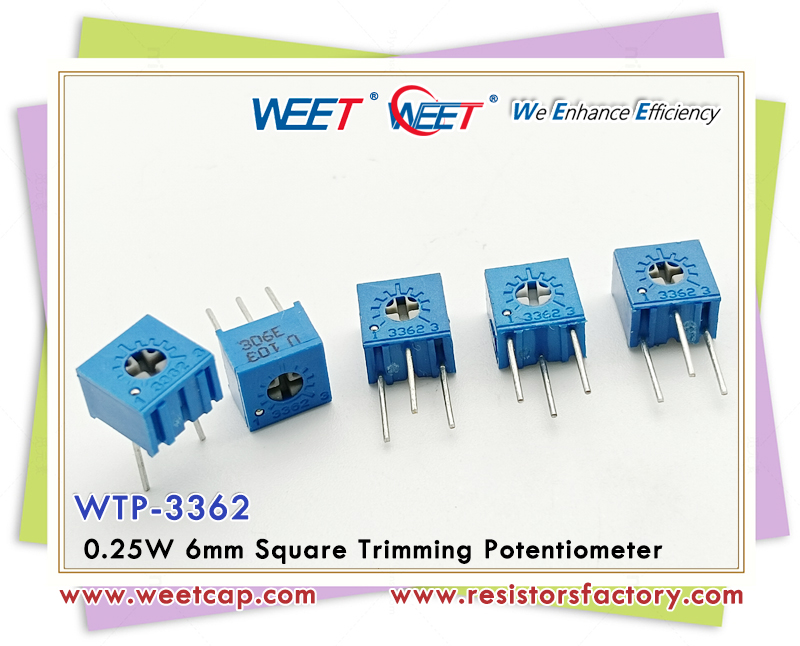

https://www.resistorsfactory.com/Datasheet/WEET-WTP-3362-0.25W-6mm-Square-Trimming-Potentiometer.pdf

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

| Standard Resistance Range | 10Ω - 5MΩ |

| Resistance Tolerance | ±10% (100Ω~1M), ±20% (R<100Ω, >1M) |

| Terminal Resistance | ≤±1%R or 2Ω (whichever is greater) |

| Contact Resistance Variation | (CRV) ≤±1%R or 3Ω, (whichever is greater) |

| Insulation Resistance | ≥1GΩ (100V AC) |

| Withstand Voltage | 640V AC |

| Adjustment Angle | 240° |

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

The working principle of the 3296 potentiometer is based on its internal structure and electrical characteristics.

It is a variable resistor, usually composed of a resistor body and a movable brush. The resistor body has two fixed ends, and the position of the moving contact point on the resistor body can be changed by manually adjusting the shaft or sliding handle. In this way, the resistance value between the moving contact and any fixed end will change, thereby adjusting the voltage and current in the circuit. twelve The 3296 potentiometer is a pre adjusted potentiometer driven by a screw, with the characteristic of multiple rotations. The full stroke is greater than or equal to 15 rotations, and the maximum resistance of the resistor body is only 300 °.

By rotating the screw, the position of the contact point on the resistor can be adjusted, thereby changing the resistance value of the potentiometer. After adjusting to the maximum or minimum resistance value, the contact will not move with further rotation of the screw, which provides protection.

Potentiometers have a wide range of applications, as they can be used to adjust voltage (including DC voltage and signal voltage) and current, and are also commonly used as voltage dividers. In electronic circuits, the 3296 potentiometer is particularly suitable for situations that require high precision, such as audio amplifiers, temperature controllers, light brightness regulators, etc

https://www.resistorsfactory.com/Datasheet/WEET-WTP-3329-0.5W-6mm-Round-Trimming-Potentiometer.pdf

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

How to distinguish the three pins of a potentiometer

The three pins of a potentiometer typically include the middle pin (wiper), top pin (top), and bottom pin (bottom).

The middle foot serves as a voltage divider, while the top and bottom feet define the resistance range that changes when the knob is turned. The method to distinguish the three pins of a potentiometer is as follows: 12 Observe the appearance. The appearance of a potentiometer usually has a mark indicating the position of the middle pin, and the positions of the left and right pins can also be distinguished by size and shape. Generally, the left pin is slightly larger than the right pin and is further away from the middle pin.

Use a multimeter for testing. Using a multimeter can further confirm the function of the pins. Firstly, connect the multimeter probes to any two pins of the potentiometer, adjust the potentiometer handle, and observe whether the resistance changes; Then, replace one of the probes with the connected pin, adjust the potentiometer handle again, and observe whether the resistance value changes. Comparing the resistance values of two measurements, when the resistance value in one measurement does not change, it indicates that the pin connected to the red and black probes of the multimeter is a fixed pin, and the other pin is a moving pin. Through these methods, the three pins of the potentiometer can be effectively distinguished.

https://www.resistorsfactory.com/Datasheet/WEET-WTP-3323-0.25W-6mm-Square-Trimming-Potentiometer.pdf

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

WEET Shares Precautions for adjustable potentiometers

1. Avoid excessive rotation

When using adjustable potentiometers, it is necessary to avoid excessive rotation to avoid abnormal resistance values or equipment damage.

2. Avoid external impact

Adjustable potentiometer is a relatively fragile component that needs to be careful to avoid external impact and mechanical damage.

3. Avoid entering high voltage

When using adjustable potentiometers, it is necessary to avoid entering excessively high voltage to prevent equipment damage or safety accidents.

4. Pay attention to temperature and humidity

Adjustable potentiometers are sensitive to temperature and humidity, and attention should be paid to the ambient temperature and humidity to avoid damage to the equipment.

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

1、 The basic principle of adjustable potentiometers

Potentiometer, also known as potentiometer and rotary rheostat, is a component used to adjust the resistance value in a circuit.

Its working principle is to change the resistance value of the resistor by rotating the knob on the adjustable potentiometer, so as to control the parameters such as current and voltage in the circuit.

2、 The usage process of adjustable potentiometers

A. Choose a suitable adjustable potentiometer

When selecting an adjustable potentiometer, it is necessary to choose according to the specific usage scenario and parameter requirements.

Usually, factors such as the resistance value, rated power, and adjustment accuracy of adjustable potentiometers need to be considered.

B. Connect the circuit

Connect the adjustable potentiometer to the circuit and adjust the knob as needed to change parameters such as current and voltage in the circuit.

C. Adjust the resistance value of the potentiometer

By rotating the knob on the potentiometer, change the resistance value of the potentiometer. Be careful not to rotate excessively or too quickly to avoid damaging the equipment.

D. Organize circuits

After use, the circuit needs to be organized to avoid short circuits or other unexpected situations.

WEE Technology Company Limited - Manufacturer For Full Range of Resistors

A potentiometer, also known as an adjustable resistor, is a basic electrical component commonly used in motors to adjust the voltage and current in the circuit, thereby achieving control of the motor. In motors, potentiometers mainly have the following functions:

1. Adjust the output voltage and current of the motor: The potentiometer can adjust the output voltage and current of the motor by changing the resistance value in the circuit, thereby controlling the working performance of the motor. For example, in a DC motor, a variable resistor can be used to control the speed and torque of the motor, as well as to adjust the winding resistance and current of the motor.

2. Suppressing interference signals in the circuit: The potentiometer can be used as a part of the filter to suppress interference signals in the circuit by changing the resistance value, thereby improving the stability and reliability of the motor's operation.

3. Adjusting the attenuator: The potentiometer can also be used as a part of the attenuator to attenuate signals by adjusting the resistance value, thereby protecting the motor and other electrical components from high signal voltages.